Effect of Microwave Drying Temperature and Material Thickness on Quality of Tieguan Yam Tablets

Absrtact: Fresh iron stick yam was used as material to dry by means of on-line control of material temperature and thickness in microwave drying by inserting optical fiber into material center, drying processing was carried out by single factor test method, polysaccharides in samples were extracted by Soxhlet extraction method, and polysaccharide yield of samples prepared by different drying parameters was determined by phenol-sulfuric acid colorimetry. The microwave drying equipment was used to record the weight and control the temperature of the material. The color difference meter was used to measure the color of the sample and evaluate the drying effect.

The results showed that the material temperature of the highest polysaccharide yield was 50 C and the whiteness value was the highest, but the drying time was the longest when the material temperature was different and the thickness was 5 mm. When the material temperature was 60 C, the material thickness of the highest polysaccharide yield was 5 mm. Comprehensive comparison shows that the drying effect of microwave drying is better when the temperature is 60 C and the material thickness is 5 mm.

Key words: yam microwave drying; temperature; thickness

Tieguan yam is the tuber of Dioscorea zingiberensis, also known as Huaiyao No. 1. It is a unique Germplasm in Chinese yam germplasm resources. It has excellent food and medicine, sweet taste and contains more than 20 nutritional and health components. It is often regarded as a "tribute" and known as "Huai Shen". As a homologous food, it has been used for more than 3000 years.

Xu Qin extracted the crude polysaccharide RDP from Dioscorea opposita, purified and separated, and obtained homogeneous polysaccharide RP. Xu Zenglai et al. studied the effects of crude polysaccharide of Chinese yam on immune function in mice. It was concluded that polysaccharide could enhance the proliferation of lymphocyte in mice, promote the production of antibodies in mice and enhance the carbon clearance ability of mice.

The high medicinal value of dried Tieguan Yam tablets has aroused people's attention and research. Ye Xiaomeng et al. used freeze-drying-microwave vacuum drying technology to dry Tieguan yam, but the drying time was long and the energy consumption was high. Chen Yuanyuan et al. investigated the effects of microwave vacuum drying on the yield and drying characteristics of Tieguan yam polysaccharides, and found that only controlling microwave power could easily lead to burnt paste when water content was low. Huang Luao et al. showed that the properties of Tieguan yam polysaccharides were stable. Under the same temperature, the processing method has no significant effect on it. However, microwave drying of Tieguan yam has not been studied.

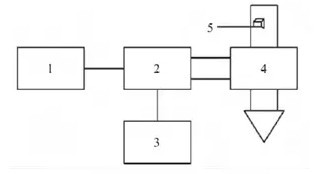

The intermittent microwave drying of Tieguan yam at fixed temperature and slice thickness has not been studied. At present, the drying weighing of Tieguan yam is generally carried out by interrupting the extraction of materials, and there are some errors in the data. In this experiment, the electric control microwave drying system developed by our research group is used for on-line measurement.

The power of microwave oven and the switch of microwave oven are controlled by Labview programming, National In-structure acquisition card, optical fiber regulator and optical fiber. Optical fiber is used to monitor the temperature of the material center in the microwave oven on-line, and the switch of the microwave oven is controlled by comparing the temperature of the material center with the difference set in the software program. In order to obtain the optimum temperature and thickness of dried Tieguan yam and provide technical support for its production, the effects of different temperature and material thickness on polysaccharide content, color difference and moisture content of Tieguan yam were studied.