Kinetics of Vacuum Microwave Drying of Purple Potato Chips

Absrtact: The drying kinetics and optimum drying conditions of purple potato chips under vacuum pressure - 0.05, - 0.06, - 0.07 MPa, microwave drying equipment 400, 500, 600 W and thickness of 2, 3 and 4 mm were studied. The results showed that the vacuum microwave drying of purple potato chips was a fast and slow process, and the microwave power had the greatest influence on the drying process of purple potato chips. The higher the power, the faster the drying rate.

The Page model was found to be the most suitable one for fitting the water ratio change of purple potato chips during vacuum microwave drying. Through the analysis of the comprehensive evaluation coefficient and membership degree of average drying rate, total color difference, anthocyanin content, swelling capacity, water absorption and oil absorption, the optimum parameters of vacuum microwave drying of purple potato chips were obtained as follows: -0.05 MPa, 400 W and 2 mm.

Key words: Purple potato microwave drying; Vacuum microwave drying; Kinetics; Functional properties; Anthocyanin

Purple potato belongs to Solanaceae Solanaceae. It has been planted in South America for many years. In recent years, it has been introduced into China and maintained an annual growth rate of 5%. Compared with ordinary potatoes, purple potatoes have higher nutritional value. Every 100g of purple potatoes contains crude fat 0.49g, starch 12.43g, crude fiber 0.83g, vitamin B10.43mg, vitamin B21.90mg, etc., and the skin and meat are rich in anthocyanins, so their antioxidant function and medicinal value are increasingly receiving. People's favor.

Fresh purple potatoes have high moisture content, are difficult to store and have high rot rate. Therefore, the selection of appropriate drying technology plays an important role in prolonging the shelf life of purple potato and retaining its active components and efficacy. The most common drying method is hot air drying. The equipment is simple, but the heat loss is large, the drying rate is slow, and the nutrients in food are seriously damaged. Liu Jiayan et al. found that freeze-drying had little damage to the color of purple potatoes and could preserve the nutrients of purple potatoes.

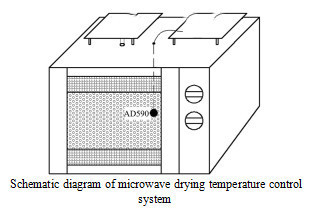

But freeze-drying has the shortcomings of long drying time and high cost. Vacuum microwave drying technology is a combination of microwave and vacuum drying technology. It has the advantages of fast drying speed, high energy efficiency, uniform product quality and easy control. It has been widely used in drying carrot slices, abalone mushrooms, tilapia and apple slices. At present, there is no report about the vacuum microwave drying of purple potato chips, and the research on purple potato chips at home and abroad mostly focuses on physiological functions, and the research on processing characteristics of purple potato is very limited.

The purpose of this study was to explore the effects of vacuum pressure, microwave power and slice thickness on drying characteristics, water ratio and other physical and chemical indicators (including total color difference, anthocyanin content, swelling capacity, water absorption and oil absorption) of purple potato chips during drying. Through comprehensive optimization, the optimum technological parameters of vacuum microwave drying of purple potato chips were obtained, which provided theoretical basis for the process research and production control of vacuum microwave drying of purple potato chips.