Effect of different drying methods on the quality of papaya

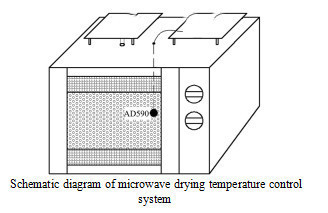

Absrtact: In order to obtain a better drying method for papaya, the effects of five drying methods on the quality of papaya powder were compared, including hot air drying, microwave drying equipment, hot air and microwave combined drying, vacuum freeze drying and microwave vacuum drying, with the content of flavonoids, total phenols, Vc, reducing sugar and ursolic acid in the dried papaya powder as the index.

The results showed that microwave drying and vacuum freeze-drying could preserve the nutritional quality of papaya powder. Considering the energy consumption and drying efficiency, microwave drying was the best drying method. This study can provide some technical references for the industrialized production of papaya powder.

Key words: papaya microwave drying; papaya powder; microwave vacuum drying

Papaya is the ripe fruit of the Rosaceae Papaya plant Hawthorn, also known as Begonia and Papaya. It is one of the first medicinal and edible foods published by the Ministry of Health. It is widely distributed in Shandong, Shaanxi, Gansu, Sichuan, Jiangsu, Anhui, Zhejiang, Jiangxi, Hunan, Hubei, Guangdong, Guangxi, Yunnan and other places.

According to the Annotation of Materia Medica Classics, papaya with smooth skin is sour, astringent and has the functions of relaxing the stomach and tendons, dispelling rheumatism, eliminating phlegm and stopping diarrhea. Modern research shows that papaya is rich in nutrients and physiological activity, and is a rare natural raw material for food, medicine and health products. Fruit and vegetable powder refers to the processing of fresh fruits and vegetables into powder products. It has become a research hotspot at home and abroad because of its rich nutrition, unique flavor, easy to preserve, easy to carry, rapid flushing and so on.

With the rapid development of modern food industry and the increasing demand for fruit and vegetable products, the development of high-quality fruit and vegetable flour will produce tremendous economic value and social benefits. The main drying methods of fruit and vegetable powder processing are natural drying, hot air drying, vacuum drying, microwave drying, vacuum freeze drying and various combination drying. The drying method has an important influence on the quality characteristics of fruit and vegetable powder.

In this study, papaya was treated by five different drying methods: hot air drying, microwave drying, hot air and microwave combined drying, vacuum freeze drying and microwave vacuum drying. The effects of different drying methods on the quality of papaya powder were investigated by evaluating the changes of flavonoids, total phenols, reducing sugar, VC and ursolic acid content in the Dried Papaya powder. The conclusion of this study can provide theoretical basis and technical reference for the industrialized production of papaya powder.