Study on Optimization of microwave drying of straw and fruit by Response Surface Methodology

Absrtact: Box-Behnken model in response surface methodology was used to study the conditions of microwave drying equipment, and a quadratic polynomial mathematical model for microwave drying of straw and fruit was established. The effects of main factors and their interactions were discussed. The results of variance analysis showed that microwave duration and microwave power had significant effects on dehydration of straw and fruit.

The optimum technological conditions are as follows: microwave drying time is 13 minutes, microwave power is 1.5 kW and material quantity is 50 G. Under the optimum technological conditions, the predicted value of dehydration of straw and fruit was 76.32%, which was close to the experimental value of 75.66%, which confirmed that the regression equation fitted well.

Key words: microwave drying of straw and fruit; response surface methodology;

Grass fruit is a perennial herb of Gingeraceae and Cardamom. It is one of the main varieties of medicinal and edible herbs. It can be used as seasoning and flavoring, and also as fruit medicine. It has the functions of warming the stomach, nourishing the stomach and reducing food and smoothing the qi. As spices, 90% of straw and fruit are mainly used in food processing, while only 10% are used in traditional Chinese medicine and other fields. In order to facilitate storage, fresh fruits and grasses harvested need to be dried.

At present, the main drying methods of straw and fruit are baking drying and natural sun drying. Traditional baking drying usually uses electric oven or oven. It requires strict control of baking temperature and time, long drying time, low drying efficiency, poor drying effect inside materials, which can easily cause deterioration. While natural sunlight drying needs to consider climate, geographical location and other factors, which are easy to be polluted, long drying time, a large number of labor-consuming and so on.

Therefore, an efficient, low-cost and easy-to-control drying method is needed to solve the problems in the traditional drying process.

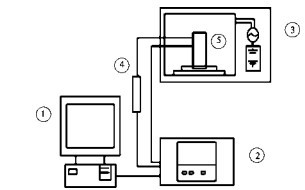

Microwave energy is a kind of clean energy. According to the different electromagnetic characteristics of materials, it can generate energy to heat materials directly. Microwave heating has the characteristics of selective heating, internal heating and non-contact heating. In this study, response surface methodology (RSM) was used to investigate the effects of various factors on the dehydration of straw and fruit under microwave conditions, so as to provide a theoretical basis for microwave drying of straw and fruit.

Microwave energy is a kind of clean energy. According to the different electromagnetic characteristics of materials, it can generate energy to heat materials directly. Microwave heating has the characteristics of selective heating, internal heating and non-contact heating. In this study, response surface methodology (RSM) was used to investigate the effects of various factors on the dehydration of straw fruits under microwave conditions, so as to provide a theoretical basis for the microwave drying of straw fruits.

The whole process of microwave drying of straw and fruit showed the law of decreasing drying speed, which accorded with the control characteristics of typical internal conditions of microwave drying. In the response surface model analysis of microwave drying of straw and fruit, the relationship between dehydration amount and microwave action time, microwave power and material quantity conformed to quadratic regression equation model; the model determination coefficient R2 = 0.9744, and the correction determination coefficient R2 = 0.9415, which indicated that the fitting degree of the model was higher; and in the variance analysis, microwave power and microwave action time were related to dehydration. Quantity effect is more significant.

The optimum conditions of microwave drying of straw and fruit were obtained by response surface optimization and verification: microwave action time 13 min, microwave power 1.5 kW and material quantity 50 G. The dehydration of straw and fruit was 75.66% under the measured conditions, which was 0.66% different from the predicted value (76.32%).