Optimization of Hawthorn hot air-microwave combined drying process

In order to explore the best drying technology and the law of moisture change in Hawthorn dried products, hawthorn was dried by hot air, microwave and combined drying. The optimum drying conditions of Hawthorn were obtained by range analysis of orthogonal experiment. The drying model of 16 kinds of fruits and vegetables was used to fit the experimental data, and the dynamic model suitable for hawthorn joint drying was determined.

The results show that the combined drying of hot air and microwave has the advantages of hot air and microwave drying equipment. The optimum conditions of combined drying are as follows: hot air temperature 75 C, water content at conversion point 50%, microwave power density 2.7 W/g. The process of hot air and microwave drying equipment of Hawthorn combined drying can be described by Approximation of diffuse model and Hii and Other model respectively. The results of this study can provide theoretical basis and technical guidance for further processing and industrial application of hawthorn.

Key words: Hawthorn microwave drying; hot air-microwave combined drying; orthogonal experiment; kinetic model

Hawthorn is rich in nutrients, high value of health care, known as "longevity fruit". Because fresh hawthorn is not easy to store and is prone to oxidation and corruption, Hawthorn processed products are mainly sold in the market, including dried hawthorn slices, hawthorn slices, fruit juice, solid beverages, etc. Among them, Hawthorn dried tablets are the most widely used raw materials for pharmaceuticals and other processed products. In China, Hawthorn chips are mainly produced by dehydration, but the dehydration process takes a long time and consumes a large amount of energy. Therefore, in order to improve production efficiency, reduce costs and obtain high-quality dry products, it is necessary to improve the existing drying process.

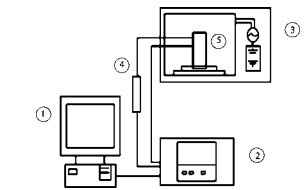

In recent years, in the field of dehydration and drying of fruits and vegetables, combined drying technology has become a new favorite of scholars. Among many combined drying methods, hot air-microwave combined drying is widely used by researchers because it combines the advantages of simple operation, short drying time and fast drying rate of hot air, and overcomes the shortcomings of long drying time, high energy consumption and uneven microwave drying. At present, scholars have studied the drying of various fruits and vegetables by hot air-microwave drying technology, such as orange peel, pumpkin slices, spinach, ginger slices, apple slices and kiwifruit.

At present, hot air drying, gas jet impingement drying, microwave hot air coupled drying and other methods are mainly used for hawthorn drying at home and abroad. There are few reports on hawthorn hot air-microwave combined drying. Therefore, hot air-microwave combined drying of hawthorn was used to explore the optimum technological conditions for obtaining high-quality dried hawthorn slices, and the applicability of the existing dynamic model of fruit and vegetable slices to describe the moisture change during Hawthorn drying was investigated. This study provides a new method for industrial production of Hawthorn dried products, and also provides a theoretical basis for the improvement and design of equipment for the production of Hawthorn dried products.