Optimizing Microwave Drying Technology of Antitussive Extracts from Apricot Shells by Orthogonal Design

ABSTRACT: Objective To optimize the microwave drying parameters of apricot shellfish antitussive extract. Methods The microwave drying technology of apricot shellfish cough extract was optimized by L9 (34) orthogonal test with microwave drying equipment, drying time, tray thickness and vacuum as the optimization factors. The microwave drying technology of apricot shellfish cough extract was optimized by L9 (34) orthogonal test.

Results The optimum microwave drying technology of apricot shellfish antitussive extract was microwave power 6 kW, drying time 9 min, paving thickness 2-2.5 cm, vacuum degree_0.08-_0.09 MPa. ConclusionThe process is efficient, energy-saving, stable and feasible, and provides experimental basis for improving the drying process of Xingbei Zhike granules.

Key words: apricot shellfish antitussive extract; microwave drying; amygdalin; praeruptorin A; praeruptorin B; orthogonal test, microwave drying of medicines

Xingbei Zhike Granule is composed of bitter almond, forehu, ephedra, Fritillaria thunbergii and other nine traditional Chinese medicines. It has the functions of clearing lung, relieving cough and asthma. Clinical studies have shown that Xingbei Zhike Granule has good antitussive and anti-allergic effects. In the actual production, apricot cough extract extract is mostly spray drying, which has the disadvantages of strong hygroscopicity, high loss, and low drying and transferring rate of indicative ingredients such as amygdalin, Alvin and alba.

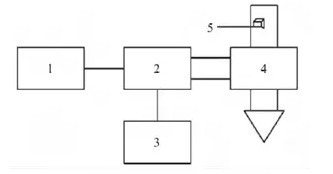

At present, the application of microwave vacuum drying technology to drying Chinese herbal extract has been studied in China. This technology is a new drying technology developed rapidly in recent years. It evaporates and dries water from the interior by heating materials and dielectrics. It has the advantages of fast drying speed, high energy utilization and even drying. In this study, the microwave drying technology of Armeniaca antitussive extract was optimized under pilot test, and compared with vacuum drying and spray drying, in order to provide experimental basis for improving the drying technology of Xing Bei Zhike granules.

Microwave drying technology can generate heat by absorbing microwave by extract itself, which can transfer heat from inside to outside. In the drying process, a large number of bubbles will be generated inside, which is conducive to the evaporation of water. Moreover, the drying process is carried out under vacuum conditions, which can greatly reduce the drying temperature and greatly shorten the drying process of Chinese herbal extract. At present, the research on microwave drying of Chinese herbal extract is mostly confined to the laboratory small-scale test stage, and there are few reports on pilot-scale and industrialization studies.

In this study, the microwave drying technology of apricot shellfish antitussive granule extract was studied by orthogonal test under pilot-scale conditions, taking the comprehensive transfer rate of index components as the evaluation index, and compared with other conventional drying processes. The results were ideal and obviously superior to conventional drying methods. This study provides a new attempt to solve the difficult drying problem of Chinese herbal extract, and provides technical support for the transition from microwave drying technology to industrial application, which has certain guiding significance.