Experimental study on drying characteristics and quality of jujube slices under different drying methods

ABSTRACT: By establishing the mass and heat transfer model of the continuous microwave drying of activated rice, the temperature and moisture content distribution in the microwave drying equipment of activated rice were obtained. Under the conditions of microwave intensity of 1.16, 2.75 and 4.34 W/g, the temperature and moisture models of activated rice were validated experimentally to determine the correctness of the heat and mass transfer model.

The results of simulation and measurement show that the microwave power can be controlled when the temperature rises slowly at the end of the continuous microwave dryer, and the energy consumption of microwave drying can be reduced. After the drying stage, the temperature inside and outside of the active rice material can be balanced, the drying effect is more uniform and the drying quality can be guaranteed. The research has guiding significance for microwave heating technology and control of active rice.

Key words: microwave drying of active rice; temperature; moisture

The continuous microwave dryer is used to dry the active rice. The distribution and change of temperature and moisture affect the drying efficiency and quality. It is the main index for the control system of microwave dryer to control the drying process. Current research on microwave drying process mostly focuses on the microwave drying characteristics of materials and the temperature and moisture changes depending on drying time.

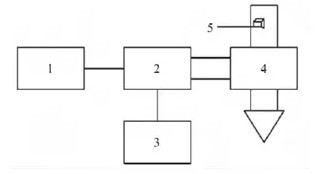

During the normal operation of continuous microwave dryer, along the movement direction of conveyor belt in the dryer, the temperature and moisture of the material can be regarded as a steady-state process, which only changes with position and does not change with time. According to the microwave drying characteristics of active rice, the steady-state distribution model of temperature and moisture of active rice in microwave dryer is established, which is helpful to analyze the changing trend of material temperature rising and moisture decreasing. It is an important basis for designing continuous microwave dryer suitable for drying active rice.

In this paper, the law of temperature and moisture content change in microwave drying process is studied. The law of temperature and moisture content change with distance in drying process is deduced by theoretical formula, and the theoretical model is verified by experiment.

On the basis of the optimum drying parameters obtained from the drying experiment, a mass and heat transfer model for continuous microwave drying of activated rice was established. The temperature and moisture content distribution in the microwave dryer of activated rice could be obtained. Under the conditions of microwave intensity of 1.16, 2.75 and 4.34W/g, the temperature and moisture models of activated rice were tested to verify the correctness of the heat and mass transfer model.

The results of simulation and measurement show that the microwave power can be controlled when the temperature rises slowly at the end of the continuous microwave dryer, which can reduce the energy consumption of microwave drying and improve the drying quality. Continuous microwave drying should enter the slow-thawing stage after the drying stage, so as to balance the temperature inside and outside the active rice material, make the drying effect more uniform, and ensure the drying quality.