Optimization of Microwave-Hot Air Combined Drying Technology for Red Shrimp and Shrimp

Taking red shrimp shrimp as the research object, using single microwave or hot air drying as the control, the Microwave-hot air combined drying process was studied based on the comprehensive values of rehydration ratio, surface color before and after rehydration, hardness, elasticity and chewiness after rehydration.

On the basis of single factor, microwave drying equipment, hot air drying temperature and water content at conversion point were selected as independent variables, and the response value was taken as comprehensive value to determine the optimum drying conditions: 250 W microwave drying, 50% water content at conversion point, and 70 C hot air drying.

Under these conditions, the comprehensive value of dried red shrimp and shrimp meat is 45.32, which is higher than that of any group of dried red shrimp and shrimp meat products. It shows that the technological parameters obtained by orthogonal optimization have practical guiding significance. The internal structure of dried shrimp products was observed by electron microscopy, which showed that combined drying was better than single drying method.

Key words: shrimp microwave drying; hot air drying; combined drying

Red shrimp, the scientific name of the Chinese tube whip shrimp, an annual benthic crustacean. Shrimp is rich in essential amino acids, unsaturated fatty acids and vitamins and other active substances, and has very high nutritional value. At the same time, dried shrimp products are welcomed by consumers because of their rich nutrition, unique flavor, storage resistance and easy to carry.

Drying production is one of the important methods of aquatic products processing, but there are various shortcomings in single drying process: natural drying is vulnerable to dust, insects and other pollution, birds, rodents invasion, resulting in loss and unsanitary; hot air drying time is long, energy consumption is high, but also reduces the quality of products; freeze drying can bring very high product quality. However, due to the long production cycle, high processing costs, low production efficiency, large energy consumption and other issues; heat pump drying in the middle and late drying, slow drying speed, long drying time, intermittent work, small drying scale, can not achieve continuous operation of materials, it is difficult to achieve mass production. Combined drying can usually solve the shortcomings of single drying method.

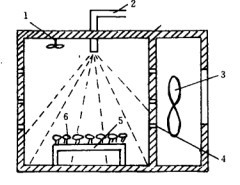

Combined drying refers to a kind of composite drying technology, which combines the advantages of two or more drying methods according to the characteristics of materials and carries out in stages. Such as: Microwave-hot air combined drying, hot air-freeze combined drying and hot air-microwave-freeze combined drying.

Nowadays, combined drying has been studied in jujube, litchi, snow lotus, tilapia, squid, croaker and other aquatic products. Most combined drying has the characteristics of fast speed and short time, high cost performance and complementary advantages, avoiding the shortcomings of single drying method. Because the epidermis hardens easily during hot air drying, which is not conducive to the internal water drainage, the combined drying method of microwave and hot air was chosen in the experiment.