Effect of different drying methods on the quality of instant apricot and abalone mushroom crisps

[Abstract] In order to select suitable drying methods for ready-to-eat apricot and abalone slices, the effects of hot air, microwave, hot air microwave and vacuum freezing on the quality of ready-to-eat apricot and abalone slices were studied with fresh apricot and abalone mushrooms as raw materials.

The results showed that the drying rate was Microwave Drying Equipment > hot air microwave drying > hot air drying > vacuum freeze drying; hot air drying had little effect on color, hardness and brittleness of products were poor, rehydration rate was low, 150%, edge shrinkage was serious; microwave drying had fast drying rate and low energy consumption, which was 2.07 (kw.h)/kg, but the product had scorch and color. Zehe had poor flavor and low retention rate of polysaccharide, which was 2.80 mg/g.

Vacuum freeze-drying has good color, high retention rate and rehydration rate of polysaccharides, which are 4.92 mg/g and 570% respectively, but its hardness is poor and energy consumption is high, which is 37.09 (kw.h)/kg. Hot air microwave drying has little effect on color, and the retention rate and rehydration rate of polysaccharides are 3.60 mg/g and 271% respectively, with moderate hardness and brittleness. Low consumption, 2.23 (kw. h) / kg, is a suitable drying method for the production of ready-to-eat apricot and abalone mushroom crisps.

Key words: Microwave drying of Pleurotus eryngii; instant food; drying method; quality

Almond and abalone mushrooms, also known as spiny celery, are rare edible and medicinal fungi with thick flesh, crisp texture and rich nutrition. Pleurotus eryngii is rich in protein, carbohydrates, vitamins, amino acids, sterols, calcium, magnesium, copper, zinc and other minerals. It has many health functions, such as reducing blood lipids, anti-cancer, improving gastrointestinal function, anti-atherosclerosis, anti-oxidation and reducing cholesterol.

Instant apricot and abalone mushroom crisps are a new type of leisure food. They are popular because of their crisp taste, rich nutrition and rich flavor.

In the processing of ready-to-eat apricot and abalone mushroom crisps, the drying process has a greater impact on the quality of ready-to-eat apricot and abalone mushroom slices. Reasonable drying method can effectively reduce the influence of processing on the color of ready-to-eat apricot and abalone mushroom slices and the destruction of nutrients, thus ensuring

At present, the commonly used drying methods in food industry, such as hot air drying, microwave drying, low-temperature frying, vacuum freeze-drying, air-flow puffing drying and the combination of several drying methods, have been applied to Apple crisps, banana crisps, mushroom crisps, Flammulina velutipes and Cigu crisps, etc. However, there is no report of hot air microwave combined drying of ready-to-eat apricot and abalone crisps.

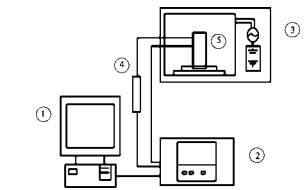

Therefore, the effects of four drying methods, hot air, microwave, hot air and vacuum freezing, on the quality of ready-to-eat apricot and abalone mushroom chips were discussed in order to screen out the suitable drying methods for the production of ready-to-eat apricot and abalone mushroom chips, so as to guide the actual production and meet the needs of people for high-quality ready-to-eat apricot and Abalon