Study on Microwave Drying Characteristics and Drying Quality of Lotus Seeds

Absrtact: In order to explore the microwave drying equipment and drying quality of lotus seeds based on temperature control, and to study the effects of different microwave power and material surface temperature range on the microwave drying characteristics of lotus seeds, the microwave temperature control drying experiment was carried out on Lotus seeds, and the quality of microwave drying lotus seeds and hot air drying lotus seeds based on temperature control was analyzed.

The results show that the surface temperature of materials has a great influence on lotus seed drying. The larger the surface temperature range of materials, the faster the drying rate and the shorter the drying time of lotus seeds. The microwave drying power has little influence on lotus seed drying. Seven common thin-layer drying models were used to fit the temperature-controlled microwave drying process. The results show that Midilli model is the most suitable thin-layer drying model for describing the moisture change rule of lotus seeds during microwave temperature-controlled drying process.

According to Fick's second law, the effective diffusion coefficient of temperature-controlled microwave drying of lotus seeds is 8.9891*10-10~2.22431*10-9 m2/s, and the activation energy of temperature-controlled microwave drying of lotus seeds is 79.85 kJ/mol from Arrhenius equation. There was no significant difference in rehydration rate between the two drying methods (p > 0.05), and the shortest drying time of lotus seeds by temperature-controlled microwave was lower than that by hot air drying. The results can provide reference for the temperature-controlled microwave combined drying process of lotus seeds.

Key words: lotus seed microwave drying, temperature control, drying kinetics, quality

The lotus seed is the mature seed of the lily plant. Lotus seed is rich in protein, vitamins and trace elements needed by human body. It can nourish deficiency, nourish heart and calm mind, enhance immunity, and has high nutritional and medicinal value. However, lotus seeds have the characteristics of short harvest time and large harvest. Fresh lotus seeds are very prone to browning during storage, resulting in the decline of lotus seed quality and loss of nutrients. Therefore, in order to effectively preserve fresh lotus seeds, it is very important to dry them immediately after harvesting them.

Nowadays, sun-drying combined with charcoal oven and oven baking are two traditional methods of lotus seed drying. However, the appearance, color and quality of lotus seeds obtained by these two methods are poor, and the nutrient loss is serious. Microwave drying technology is widely used in the drying field, with the advantages of high drying efficiency, good drying quality and simple operation. The effects of microwave drying intensity on the rehydration performance, color and shrinkage of oysters were studied.

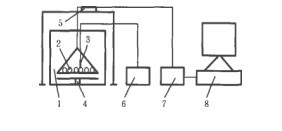

Moxiu et al. designed a constant temperature control system for microwave drying, so that the temperature of materials during drying is in a preset temperature range, in order to ensure the quality of drying materials. Chen Lin and others compared the difference of peanut quality between temperature-controlled microwave drying and conventional microwave drying.

The results showed that the peanuts dried by conventional microwave had coke paste, and the peanuts dried by controlled temperature microwave had no coke paste, and the drying effect was better. Zhang Wei and others used temperature-controlled microwave drying to dry Salvia miltiorrhiza and compared the quality of its dried products with conventional shade-drying, sun-drying and hot air drying. The results showed that temperature-controlled microwave drying could improve the quality of Salvia miltiorrhiza and reduce the loss of effective ingredients.

At present, there are few studies on temperature-controlled microwave drying of lotus seeds. In order to study the microwave drying characteristics of lotus seeds under temperature-controlled condition and the effect of temperature-controlled microwave drying on the quality of lotus seeds, the dynamic characteristics of temperature-controlled microwave drying of lotus seeds were established, and the rehydration rate of lotus seeds after temperature-controlled microwave drying and hot air drying was compared and analyzed, which provided a theory for temperature-controlled microwave drying process of lotus seeds. On the basis.