Effect of Hot Air and Microwave Drying on Longan Quality

Abstract: In order to obtain high quality dried longan products, the quality changes of longan pulp during hot air and microwave drying were studied and analyzed.

The results showed that the changes of pulp browning degree under two drying methods were related to the activity of polyphenol oxidase (PPO); the activation of catalase (POD) activity was related to the moisture content of pulp; the sensitivity of PPO to temperature was higher than that of POD; ascorbic acid browning was not the main cause of pulp browning; microwave drying was more uniform under double stacking thickness, resulting in better texture of longan.

Through comparison and analysis, the efficiency of microwave drying equipment is significantly higher than hot air drying, and the browning degree and PPO activity of pulp under microwave drying are lower than hot air drying, so microwave drying method is more suitable for longan drying process than hot air drying method.

Key words: longan microwave drying; hot air drying; microwave drying; catalase; polyphenol oxidase; texture

Longan pulp is delicious, unique flavor, rich in vitamins and carbohydrates. Longan is abundant in summer, with strong respiratory metabolism and perishable fresh fruits. Except for a small amount of fresh food, most of them depend on drying preservation. Suitable drying technology and equipment can effectively inhibit the reproduction of microorganisms and facilitate the long-term preservation of dried products. The traditional drying method of longan in China is hot air drying. The moisture content of dried longan is lower than 20%, and the shelf life of dried longan is significantly longer than that of fresh longan.

With the research of longan industry processing technology and product development, more drying methods such as microwave drying and vacuum freeze drying have been applied to the drying process of longan. Different drying methods have different drying principles, so their effects on the preservation of longan nutritional quality and storage performance are also different. The effects of hot air drying and microwave drying on the drying quality of longan pulp were studied. The changes of nutrient quality and related enzyme activities of longan pulp in different drying stages were analyzed.

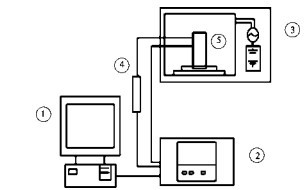

Two-stage microwave heating-batch process was adopted. Microwave power is constant at 800 W. The first stage: heating time 10 seconds, intermittent time 50 seconds; when the moisture content in the sample drops to 40%, the second stage: heating time 5 seconds, intermittent time 40 seconds. Longan dried after color protection and treated for 5, 10, 20, 40, 80, 120 and 160 minutes were used to detect moisture content. Longan dried after color protection and treated for 10, 20, 40, 80 and 160 minutes were used as the objects of other physical and chemical indexes.

In order to study the effect of microwave on the quality uniformity of longan dried after color protection, the single layer, double layer and three layer stacking were placed in the microwave oven to dry in order to study the effect of microwave on the quality uniformity of different stacking thickness.