Study on Jasmine Tea Made by Different Drying Methods

The quality of jasmine tea produced by five drying methods was analyzed, and the results showed that the jasmine tea made by low-temperature vacuum-hot air combined drying method was better than the jasmine tea made by freeze-vacuum drying method.

Its tea polyphenols, amino acids, flavonoids, water extracts are slightly lower, but the content of jasmine tea is relatively higher than that of other drying methods (hot air, microwave drying equipment, low-temperature vacuum). In terms of sensory quality, the jasmine tea made by low-temperature vacuum-hot air combined drying method is obviously superior to that made by other drying methods.

Key words: drying method; microwave drying of jasmine tea; bass processing; quality

Jasmine is an evergreen shrub of the genus Jasmine in the family Oleaceae. Jasmine tea is one of the special tea with a long history in China. It is popular with consumers because of its fresh and elegant flower fragrance and mellow tea taste. At present, the research on jasmine tea mainly focuses on the influence of water content, stack temperature, flower allocation and time on the quality of jasmine tea, while few studies have been reported on the aroma release of jasmine and the characteristics of tea.

Different drying methods of green tea lead to different changes in the physical structure of products. This paper studies the effects of different drying methods on the quality of jasmine tea products, with a view to producing high-grade jasmine tea and expanding the processing theory of jasmine tea for peer reference.

According to the existing research results, the traditional theory of tea aroma absorption mainly includes pure physical adsorption and the coexistence of chemical adsorption and physical adsorption. Due to the lack of sufficient experimental basis for chemical adsorption theory, pure physical adsorption theory dominates. The Aroma Absorption of tea depends on the adsorption of tea surface on capillary condensation. The larger the porosity of tea, the larger the specific surface area, the stronger the adsorption capacity of tea surface.

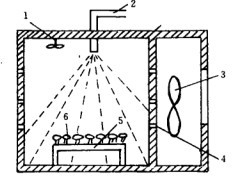

Krokida M K et al. studied the effects of different drying processes on the volume density and porosity of materials. When the moisture content is constant, the porosity of freeze-drying materials is the highest, followed by microwave, vacuum and convective drying. It can be seen that the freeze-vacuum drying green tea has the highest porosity and the strongest Aroma Absorption ability, but the tea fragrance and flower fragrance are distinct, translucent and translucent.

In low temperature and vacuum drying, the appearance, color and nutritional components of green tea are fully retained, and the porosity is relatively large. After hot air drying, the aroma of green tea can be further developed; the jasmine tea produced by traditional hot air drying is more popular, and can not meet the current demand for high-quality tea; the jasmine flower made by microwave drying green tea jasmine Tea quality factors such as aroma, taste and appearance are poor due to local overheating of green tea.