Effect of different drying methods on the quality of Yinbai granules

Absrtact: The effects of microwave spouting drying, microwave drying equipment, hot air drying and vacuum freeze drying on the quality of Zizania latifolia were studied with Zizania latifolia granules as experimental materials. The water rehydration, color difference, texture and Vc retention were compared as reference indexes, and the energy consumption and drying time were also studied.

The results showed that vacuum freeze-drying had the best quality but the highest energy consumption, which was 20 times higher than microwave jet drying; microwave jet drying had better quality than hot-air drying, and the energy consumption of hot-air drying was 7 times higher than microwave jet drying; microwave drying had the shortest drying time and the lowest energy consumption, but the quality was the worst. Considering the comprehensive consideration of energy consumption and quality, microwave jet drying is a very potential drying method.

Key words: microwave drying of Zizania latifolia; quality; energy consumption

Yinbai is white, sweet, tender, delicious, and has a variety of diets. After cooking, Yinbai can be a variety of delicacies with its own characteristics. Yinbai is not only a delicacy on the table, but also can be used as medicine. Zizania latifolia is sweet and cold in nature. It has the functions of clearing away heat and irritation, detoxifying and diuretic stools. Zizania latifolia can also withdraw milk, which has certain auxiliary effect on jaundice hepatitis and postpartum hypogalactia.

It is very seasonal and easy to lose water after harvest, which leads to wilting. It is difficult to preserve it at room temperature for only 3-5 days. Over a long period of time, there will be such phenomena as yellowing of stubble shell, flesh green, fibrosis, mildew, softening and even decay, which will affect food taste. In order to prolong the shelf life of fruits and vegetables, many drying methods are used for dehydration of fruits and vegetables in the food industry. Conventional air drying methods need high temperature and long time drying to remove moisture, which may cause serious damage to the flavor, color and nutrition of dried products and decrease the rehydration ability.

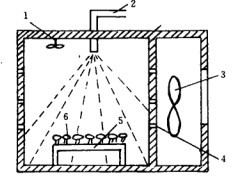

The main shortcomings of hot air drying are low energy utilization rate and low thermal conductivity in the slow drying stage. It is not easy to transfer heat to the interior during conventional heating. Compared with conventional hot air drying, microwave drying is fast, uniform and efficient. Although microwave drying has a higher drying rate than traditional drying, due to the randomness of microwave field distribution in space, the heterogeneity of microwave drying results in coking of some materials. The combination of microwave and hot air drying can overcome the shortcomings of single microwave drying.

The advantages of combined drying method complement each other, avoiding the disadvantages of single drying method, such as hot air drying food easy to shrink and color, product surface forming a hard shell, flavor loss, incomplete rehydration, and through hot air combined with microwave drying to minimize these shortcomings.

The drying characteristics of microwave jet drying and other drying methods of Zizania latifolia and the main quality indexes of dehydrated Zizania latifolia were evaluated by using Zizania latifolia granules as raw materials.