Study on High Power Microwave Drying Technology of Pepper

Absrtact: Orthogonal experiment of pepper microwave drying was conducted with water loss rate of pepper and microwave drying equipment as evaluation indexes. The effects of microwave drying parameters on pepper drying quality were comprehensively analyzed. The optimum drying parameters of pepper were obtained as follows: microwave power of 4000W, drying time of 20min, pepper treatment method of drilling holes on pepper surface and microwave working mode. It is 180 s/180 s intermittent heating mode.

Key words: pepper microwave drying; high power; microwave drying; orthogonal test

Pepper has a high content of pigments, which can be used as industrial raw materials to extract natural pigments. It has a certain position in agricultural products and broad market prospects. Chili pepper is widely planted in China. It is widely planted in the South and north. At present, the degree of mechanization of pepper drying in China is very low. The main reason is that there is no efficient and low-cost drying machine for pepper industry.

Natural air drying is characterized by long drying time, large workload, poor hygienic conditions, easy to cause mildew reproduction, high product wastage, and limited by weather and site. Therefore, it is people's expectation to design and develop a kind of drying equipment with compact structure, simple operation, automation, continuity, low input, high output, low energy consumption and high quality.

Microwave drying has its unique advantages, such as high energy conversion efficiency, sterilization, automation and continuity. However, there are few studies on high-power microwave drying of fruits and vegetables. He Mingyi and other studies show that the moisture content of fruits and vegetables is more than 80%, and it takes time for water to escape during drying, and the heating temperature should not be higher than 80 C, so as to avoid "cooking" phenomenon.

In addition, the efficiency of microwave heating is not high when the material is laid on a single layer, while the water escapes from the stack is blocked by stacking, and the "cooking" phenomenon is more likely to occur in the middle of the stacking area. Therefore, from the aspects of equipment investment, processing cost and quality of processed products, high-power microwave equipment is not suitable for fruit and vegetable drying.

However, this paper holds that high-power microwave drying of fruits and vegetables can be used to dry fruits and vegetables with high-power microwave as long as the drying technology is reasonably designed, the reasonable thickness is stacked, the drying process temperature is controlled to be less than 70 C, so that no "cooking" phenomenon occurs, and the working efficiency of microwave is improved as much as possible.

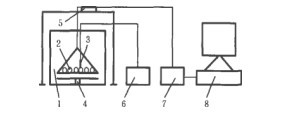

In this paper, the effects of high power microwave on the drying quality of pepper under different drying processes were studied, in order to find out the technological process that can ensure the drying quality and efficiency of pepper, and provide the basis for the design and research of industrial drying equipment.