Current Situation and Development Trend of Chinese Jujube Drying Technology

ABSTRACT: With the increase of the annual output of jujube in China, the traditional drying technology has not met the drying requirements. In view of the limitations of traditional natural drying of jujube, the advantages and disadvantages of microwave drying equipment for jujube and its working principle were expounded.

At the same time, the development trend of Chinese jujube drying technology was pointed out and explained. Finally, it was clarified that the combined drying technology was still the future direction of domestic development, and the drying technology was developing towards the direction of intelligence and automation.

Key words: jujube microwave drying; drying technology; current situation; development trend; combined drying

There are about 50 countries with jujube trees in the world, but no economic cultivation has been formed. In addition to the three northeastern provinces and Qinghai province, other provinces, municipalities and autonomous regions in China have jujube tree distribution. At present, the area of jujube trees in China is about 1867,000 hm2, with an annual output of 447,000 tons. According to the population of 1.3 billion, the per capita fresh jujube occupies 3.4 kg, and the drying rate is 60%, which is about 2 kg per capita.

Over the past 10 years, jujube has developed rapidly in southern Xinjiang, its area and output have expanded rapidly, and its management technology has improved continuously. Up to now, China is still a big jujube-producing country in the world, the cultivated area of jujube and the annual output of jujube account for more than 95% of the world, and the planted area of jujube has been increasing in recent years, and the output has also increased year by year, which occupies a leading position in the international market of jujube production.

The sugar content of jujube is high. The sugar content of fresh jujube is about 19%-44%, and that of dry jujube is about 50%-87%. The calorific value of jujube pulp is about 1293 kJ per 100 g, which is similar to wheat flour (1427 kJ), and jujube contains 18 amino acids needed by human body. Jujube protein is mainly composed of amino acids, so it is called "woody grain" and "iron crops".

It is rich in a variety of vitamins, especially the high content of vitamin C, so fresh jujube is also known as the "vitamin pill" reputation, but also rich in iron, zinc, calcium and other mineral elements. However, the biggest disadvantage of jujube is that it is easy to rot for a long time and damage during transportation. In the processing of jujube products, drying is still the most important primary processing method of jujube at present. Therefore, the drying technology of jujube is an indispensable and important link in the process of jujube processing.

Drying is the operation process of removing water from objects in order to prevent its decay and deterioration and facilitate storage. There are two common drying methods: one is natural drying, which is carried out in the atmosphere, commonly known as sun drying, blow drying and air drying. This method uses the solar radiation heat or wind in nature to gasify the water in jujube, so as to achieve the purpose of removing water, without manual heating and discharging drying medium.

The advantages of this drying method are simple and convenient, low cost, bright color and less wrinkles on the pericarp of dried jujube, but the disadvantages are limited by natural conditions, long drying time, difficult to control the process and drying process to meet the requirements, poor product quality, especially the loss of vitamin C.

The second is artificial drying method. The basic factors of material (jujube) drying are mechanical energy, physical and chemical energy and heat energy manufactured by man. The suitable drying methods are mechanical drying, physical and chemical drying and heating drying. They have the advantages of fast drying speed, high production efficiency, good quality of dried products and clean and sanitary material (jujube). The disadvantage of this method is that it needs to consume energy, has strong technicality and high production cost.

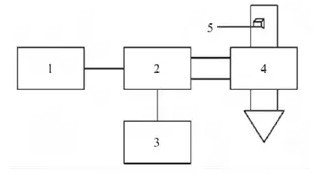

At present, most of the methods of removing water by heating are to vaporize and remove the water in the material (jujube) by means of heat energy, conduction or radiation through the medium, so as to achieve the purpose of drying. China's artificial drying technology is divided into hot air drying technology, infrared drying technology, microwave drying technology and solar drying technology.