Effect of Vacuum Microwave Drying on Quality of Okra

Absrtact: The effect of microwave drying equipment on the quality of okra was studied. Through the experiments of vacuum microwave drying okra under different drying time, vacuum degree and microwave power, the curves of color difference, fracture, rehydration rate and vitamin C content were obtained.

The results showed that with the increase of microwave drying time and microwave power, the chromatic aberration of dried okra products was larger than that of fresh fruit, but decreased with the increase of vacuum. When the drying time was at a higher level of 14 min and 16 min, the fracture of dried okra products was smaller, brittleness was better, and the fracture decreased with the increase of vacuum. The shrinkage rate and rehydration rate increased with the increase of time and microwave power.

But when the time exceeds 14 minutes, the rehydration rate decreases. When the vacuum degree increases, the rehydration rate increases obviously at the initial stage and slowly at the later stage. The greater the drying time and power, the more the loss of vitamin C, the greater the vacuum degree, the more the retention of vitamin C.

Key words: okra microwave drying; vacuum; microwave; drying; quality

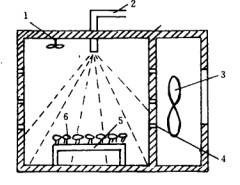

Vacuum microwave drying is based on vacuum drying and microwave drying. It combines the low temperature of vacuum drying with the fast energy transfer characteristics of microwave heating, so as to improve the efficiency and product quality. Vacuum microwave technology is generally believed to be able to produce high-quality food. At present, vacuum microwave technology has been applied in many food fields, but the research on okra is rarely reported.

Okra is a plant name, alias okra clip, carob. Originated in Africa, it entered the Americas [7]. Now Okra is distributed and cultivated in all parts of China. Okra fruit has unique flavor and high nutritional value. It can be stored for 7 days in cold storage at 0 ~5 (?) C, while it can only be stored for 2 ~ 3 days at room temperature. If it can not be processed in time, it can not be eaten.

Taking fresh okra fruits as the research object, the effects of vacuum microwave drying conditions on the quality of okra fruits were studied by investigating the quality indexes of okra fruits after vacuum microwave drying, which provided scientific basis and theoretical reference for the research of vacuum microwave drying technology of okra and promoted the development of processing technology of okra.

In the process of vacuum microwave drying, drying time, vacuum degree and microwave power all affect the quality of okra dried products. The bigger the drying time and microwave power, the more serious the browning and the bigger the color change. With the increase of vacuum, the color difference becomes smaller and the color of dry products becomes better.

In the selected drying time range, when the drying time is longer, the fracture is smaller, which indicates that the brittleness of the dry products is better, and the fracture decreases with the increase of vacuum degree and microwave power.

The shrinkage rate of okra increases with the increase of time and power, and decreases with the increase of vacuum. The longer the drying time, the higher the rehydration rate, but the longer the drying time, the lower the rehydration rate; the higher the vacuum degree and microwave power, the higher the rehydration rate. The retention rate of vitamin C decreases with the prolongation of drying time, increases with the increase of vacuum, and decreases with the increase of microwave power.