Study on the combined drying method of hot air and microwave for Angelica sinensis

ABSTRACT: OBJECTIVE To study the feasibility of processing Angelica sinensis by hot air-microwave combined drying, and to evaluate the quality of processed Angelica sinensis. Methods The hot air drying temperature, time, microwave drying equipment and microwave drying time were investigated.

According to the indexes of Chinese Pharmacopoeia 2015 edition, the quality of processed Chinese Angelica was evaluated, and the optimum technology was selected according to the quantity and productivity of microorganisms. The quantity of microorganisms, heavy metals and harmful elements and 10 kinds of active ingredients (ferulic acid, sonoprolide ferulic acid, ligustilide I, Ligusticum Ligusticum Ligusticum ligusticum, Ligusticum Ligusticum ligusticum) were detected respectively. Ester H, ligustilide A, E-ligustilide, Z-ligustilide, n-butenyl phthalide, riligustilide and Angelica lactone A) content.

Result The optimum drying process was determined to be hot air drying (70 C) for 20 H + microwave drying (100 mA) for 6 min. The number of microorganisms in the samples processed by the new method was similar to that of sulfur fumigated samples. The heavy metals and harmful elements in the samples processed by the new method did not exceed the standard, and had no significant effect on the active ingredients of medicinal materials. CONCLUSION The physical and chemical indexes of Angelica sinensis processed by the new method are in line with the provisions of the Chinese Pharmacopoeia 2015 edition. The combined drying technology of hot air and microwave can be used as a fast drying method in the processing of Angelica sinensis.

Key words: Angelica sinensis microwave drying; hot air-microwave drying technology; quality evaluation; microorganisms; heavy metals

Angelica sinensis is the dry root of Angelica sinensis, which belongs to Umbelliferae. It was first recorded in Shennong Herbal Classic. Angelica sinensis produced in Gansu has the advantages of long planting history, large planting area and good quality, which is called genuine medicinal materials.

In the local processing of Angelica sinensis, sun-drying and shade-drying are often used as the drying methods of medicinal materials, but in the case of rainy and cloudy days can not be dried in time, sulfur fumigation is often used in the processing, which makes Angelica sinensis easy to dry and beautiful in appearance, and can effectively prevent the mildew of raw worms and prolong the storage time.

It was found that sulfur fumigation could lead to the transformation of active ingredients, the decrease of efficacy, the residue of harmful substances and the increase of toxicity. Therefore, the research and development of rapid drying technology which can not only achieve the purpose of sulfur fumigation and mildew prevention, but also overcome its shortcomings is an important issue to be solved urgently.

Hot air drying technology has the advantages of low cost, less investment, no residual poisons and easy removal of the outer layer moisture of medicinal materials; microwave drying technology has the advantages of sterilization and easy removal of the inner layer moisture of medicinal materials. Previous laboratory experiments showed that the quality of Angelica sinensis processed by Yin-dry method was the best, but it took a long time. Hot air drying method could retain the main ingredients of Angelica sinensis to the greatest extent, and the efficiency was low in the later drying stage.

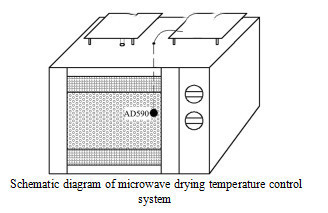

Microwave drying method can retain the amount of ligustilide, the main component of Angelica sinensis, and the drying efficiency is high. If the hot air and microwave technologies are combined, their respective advantages can be brought into play. Therefore, the feasibility of rapid drying Angelica sinensis by hot air combined with microwave drying and sterilization technology was studied.