Effect of Microwave Drying on Drying Characteristics and Quality Characteristics of Sea Cucumber

Abstract: In order to improve the drying time of heat pump and the poor quality of microwave drying equipment, the effects of microwave combined drying on the drying characteristics and quality characteristics of sea cucumber were studied. The different drying temperatures and water content of different switching points were proposed. The heat pump microwave combined drying method was used to study the changes of water content, drying rate, shrinkage rate, rehydration rate, appearance, histomorphology and odor of sea cucumber.

The results show that the heat pump microwave combined drying shows obvious segmentation characteristics. The maximum drying rate in the microwave drying stage is much higher than that in the heat pump drying. The segmental thin layer drying model can simulate the drying characteristics of the sea cucumber. In terms of dry product performance, the rehydration rate of the pure heat pump dried product is lower than the joint drying at the same drying temperature, but the shrinkage rate is greater than the joint drying.

In the heat pump microwave combined drying, the rehydration rate of dry products gradually decreases with the increase of drying temperature, but the shrinkage rate increases gradually. The time of heat pump microwave combined drying to microwave drying needs to be comprehensively determined by comprehensive drying time and finished product performance. Corresponding to the drying temperature of 40 °C and the moisture content of the conversion point is 197%, the quality of the dried product is the best and the drying time is shorter. It is a better method of joint drying of sea cucumber.

Key words: microwave drying of sea cucumber; heat pump microwave combined drying; thin layer model; water content; drying characteristics; finished product characteristics

The Stichopus japonicus production area is distributed in the Liaodong Peninsula and Shandong Peninsula of China. It is the single species with the highest median value and profit of marine aquaculture species in China, and has very high nutritional value and medicinal value. Sea cucumber is easily self-dissolving and needs to be processed as soon as possible after harvesting. Drying is the main processing method currently used. It is commonly used in the form of salt drying and freeze-drying. However, salt dryness has the disadvantages of large loss of nutrients and high energy consumption in freeze-drying. With the advancement of drying technology, new methods of drying sea cucumber have appeared.

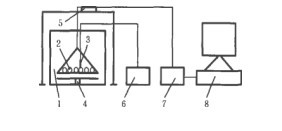

Heat pump drying is a device that recovers sensible heat and latent heat in dry exhaust gas and converts it into high-temperature heat energy heating device. Its dehumidification energy consumption ratio is up to 10 times that of traditional hot air drying, and it has the advantages of high energy utilization efficiency, energy saving and environmental protection. , but drying takes too long. Microwave drying is the principle of selective heating of water by radiation. It can heat the inside and outside of the material at the same time. It has the advantages of fast heating speed, high drying efficiency and sterilization. However, it is easy to cause the product to smash when it is used to dry materials such as sea cucumber. , affecting product quality.