Present Situation and Countermeasure of Tea Drying Technology

Absrtact: Drying is a very important process in tea processing, which directly affects the sensory and quality of tea. The application principle of microwave drying equipment is the function of heat and force. After water loss, the physical properties and endogenous components of tea changed rapidly, forming the unique sensory quality of tea.

This paper mainly analyses the principles and characteristics of various tea drying technologies in China, points out the present situation and application of tea drying technology, and discusses the corresponding countermeasures and prospects for reference.

Key words: tea microwave drying; drying technology; development; prospect

Drying is an important process in the initial processing of tea. Tea produces different sensory qualities while removing excess moisture. In recent years, with the sustained development of China's economy, more and more tea consumers have become aware of their health. Tea processing technology has gradually developed towards the direction of green, environmental protection, low carbon and energy saving, which makes up for the past tradition. Defects of clean coal and wood energy.

In order to ensure the maximum preservation of tea active ingredients in the process of processing, it is necessary to adopt effective drying technology for vegetables and other agricultural products on the basis of traditional drying technology, and carry out more effective drying research. Technology.

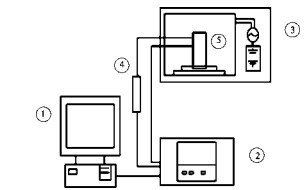

Microwave drying technology microwave mainly refers to the electromagnetic wave with a wavelength of 1 mm~1 m and a frequency range of 3*102~3*105 MHz. When drying, there is microwave radiation on the drying material, so the polarity of water in the material rotates due to the increase of microwave frequency, and various materials will produce friction heat. Whether the surface temperature or the internal temperature rises, a large number of water molecules will overflow from the material to achieve the drying effect.

Compared with other drying technologies, microwave drying technology has the advantages of fast heating speed, high thermal efficiency, uniform heating and no heating environment. Automatic control is convenient for continuous production. In the past, the initial drying methods of tea usually produced better tea colours, many of which were grey green and blue. Microwave drying technology itself has the effect of green preservation. These qualities are needed for the processing of green tea and oolong tea. The main points of the study.

For example, some scholars have compared traditional drying technology with microwave technology in their research. The results showed that the microwave technology was more uniform than the traditional method in heat treatment of leaves. The processed green tea components retained a large amount of aroma and reduced the aroma. The loss of green tea decreased significantly after microwave treatment. By comparing the effects of microwave and traditional drying technology on biochemical factors of strip green tea, it was found that the effect of microwave treatment on soluble sugar, tea polyphenols, caffeine and water extracts of strip green tea was higher in a short time, and the sensory effect was better. Chestnut type, microwave drying more fragrant.