Effect of Microwave Drying Conditions on the Quality of Zanthoxylum bungeanum

Absrtact: The purpose is to explore the application conditions of microwave drying equipment in pepper drying. The effects of microwave drying power, drying time and paving thickness on the drying quality of pepper were investigated through comprehensive evaluation of five indexes, namely, color, aroma, numbness, moisture content and seed bursting rate.

The results showed that the effects of microwave conditions on the drying quality of Zanthoxylum bungeanum L. were as follows: microwave drying power > microwave drying time > paving thickness. When microwave drying power is 480W, drying time is 4min, and the thickness of pepper paving material is 4cm, the quality of pepper is the best.

Key words: microwave drying pepper; quality

Prickly ash, a perennial shrub or small tree of Rutaceae, is one of the eight traditional condiments in China. China is the largest producer of Chinese prickly ash, mainly distributed in Shaanxi, Hebei, Sichuan, Gansu, Shanxi, Shandong and other places, especially in the South and southwest provinces of the Yangtze River.

Pepper is fragrant and nutritious. Many studies have shown that Zanthoxylum bungeanum contains protein, amino acid, glutamic acid, etc. The seeds are also rich in calcium, magnesium, sodium, iron, zinc, selenium, manganese, vitamin E and trace elements. Peel can be widely used as seasoning. In addition to edible and made into pepper seasoning, the development of a series of pepper processing products such as condiment oil and emulsified oil has become a research hotspot at home and abroad.

Among all kinds of applications of Zanthoxylum bungeanum, the amount and demand of dry Zanthoxylum bungeanum are the largest. At present, the common drying methods of fresh pepper are: traditional drying method, hot air drying, and vacuum freeze drying. These drying methods generally have many problems, such as long drying time, uneven drying, low drying efficiency, and poor quality and flavor of dried pepper, so they are not suitable for the current production situation.

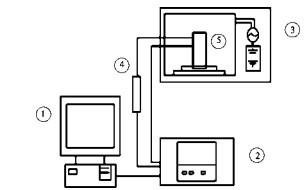

Microwave drying technology is a process of direct evaporation of water in Zanthoxylum bungeanum by using internal heat generation to form strong vapor pressure. It has the characteristics of fast drying speed, high thermal efficiency, high product quality, small occupied area, easy maintenance, no pollution after drying and no damage to products. Microwave drying technology is widely used in food industry such as grain, tea, silkworm cocoon, tobacco and so on, and has obtained considerable economic benefits.

This paper aims to explore the application of microwave drying technology in pepper drying. The effects of microwave drying power, drying time and thickness of paving materials on the drying quality of pepper were investigated through comprehensive evaluation of five indicators of color, aroma, numbness, moisture content and explosion rate of dried pepper, in order to find the most suitable technological conditions for microwave drying pepper.

The microwave drying quality of Zanthoxylum bungeanum is related to microwave drying power, microwave drying time and paving thickness. The order of affecting the quality of Zanthoxylum bungeanum is heating time > heating power > paving thickness of Zanthoxylum bungeanum bungeanum.

Through the analysis of single factor test and orthogonal test above, the optimum technological conditions for microwave drying of Zanthoxylum bungeanum are as follows: heating power 480W, heating time 4min, and the thickness of Zanthoxylum bungeanum material 4cm. In this way, the comprehensive score of Zanthoxylum bungeanum reaches 80 points, and the drying quality of Zanthoxylum bungeanum is the best.

Compared with traditional drying pepper, microwave drying speed is faster, pepper quality can be guaranteed, especially suitable for modern industrial production requirements.