Microwave drying process of peanut based on temperature control

Abstract: This paper mainly studies the effect of temperature-controlled microwave drying equipment on peanut, using self-made temperature-controlled microwave drying equipment to study the difference of peanut quality between conventional microwave drying and temperature-controlled microwave drying, in order to verify the superiority and usability of temperature-controlled microwave drying. The results showed that the peanuts were scorched by conventional microwave drying, and the drying effect was very poor. The peanuts dried by temperature controlled microwave drying had no scorching phenomenon, the skin was smooth, the cotyledons were smooth and fresh, and the drying effect was ideal. The experiment proves that the microwave drying with temperature control can guarantee the quality of Peanut after drying at the power of 1.2 W/g and the temperature range of 45-50 ~C.

Keywords: microwave, drying, temperature control, peanuts

Quote

Microwave is usually electromagnetic wave with penetrating characteristics of 300 MHz to 300 GHz. Microwave heating is based on the principle of dielectric loss. The water molecule in the material is polar molecule. Under the action of microwave, its polar orientation changes with the change of external electromagnetic field. Microwave drying is the principle of evaporating polar molecule by using the action of microwave on polar molecule. The drying speed can be adjusted by a djusting the power of microwave drying. Microwave drying technology has been applied in light industry, food industry, chemical industry, agriculture and agricultural products processing in developed countries; microwave drying technology in China began in the 1970s, and now many agricultural products have been successfully used in microwave drying. However, the measurement and control of temperature during microwave drying is still not mature enough. In conventional microwave drying, the temperature of crops rises rapidly, and the quality of crops fluctuates greatly after drying, even the internal scorching of crops occurs. Temperature-controlled microwave drying can make the drying temperature of crops in a set range to ensure the quality of crops after drying, but at present, temperature-controlled microwave drying technology is still less in research and application.

In this paper, through the conventional microwave drying and temperature-controlled microwave drying experiments, the moisture content and sensory of peanuts were compared to verify the advantages of temperature-controlled microwave drying, which provides a theoretical basis for the popularization of crop drying technology and the design of equipment, and provides technical support for industrial management.

0 test equipment and materials and methods

0.1 test materials

1) material selection: fresh red skin peanuts are produced in Yucheng District, Ya'an City, Sichuan province.

2)

Material handling: using screening machine for initial screening, the size of the material is basically the same and the grain is full. The screened peanuts were sealed in 100 g each and placed in the fridge at 4~8 C for storage.

0.2 equipment and instruments

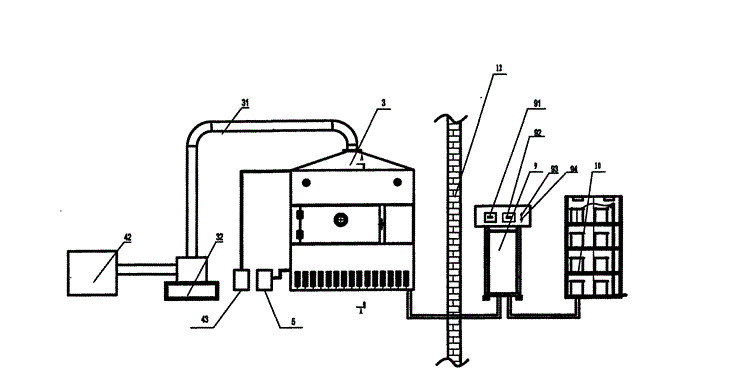

Drying equipment: self-made microwave temperature control drying equipment, with the Grace WBBH0809 microwave oven as a platform, the addition of AT89S52 microcontroller,

AD590 temperature sensor, ADC0804, A/D conversion chip, 74HC573N latch, relay and digital display block hardware. According to the test requirements, the temperature measurement and control system is designed. According to the characteristics of peanut, the corresponding temperature range is set in the program of single chip microcomputer. The temperature sensor is used to measure the real-time temperature in the drying process. When the upper temperature limit is reached, the working power supply of the microwave oven is automatically cut off, so that the temperature of the crops is reduced, and the working power supply of the microwave oven is automatically closed until the lower temperature limit is reached, and the heating is continued. This experiment has been in a continuous working state, through the peanut microwave equipment intermittent work, and then realize temperature control drying process.