Effect of microwave drying on the properties of ginger powder

Abstract: The microwave drying process of ginger powder was studied. The effects of microwave drying conditions on the yield, sensory quality, bulk density and hydration ability of ginger powder were studied. The results showed that under the microwave drying conditions of 480 W and 20 min, the yield of ginger powder was high, the sensory quality was good, the packing density was the lowest, and the hydration ability was the strongest.

Key words: ginger; microwave drying equipment; ginger powder characteristics

Ginger is a perennial perennial herb of Zingiber officinale. Ginger is rich in rhizomes and contains volatile components such as ginger oil and ginger. Ginger has a special aroma and spicy taste. It is not only one of the important condiments in people's daily life, but also one of the traditional Chinese medicines. It is one of the important specialty vegetables in China. In addition, ginger oil and other extracts are also important spices in the food industry, widely used in ice cream, candy and other foods. Oral administration of ginger can cause vasodilation and central nervous excitement, promote blood circulation, raise blood pressure, increase perspiration, but also regulate respiration, conducive to metabolism. Ginger can stimulate nerve endings in the digestive tract, cause gastrointestinal peristalsis, increase the secretion of saliva, gastric juice and intestinal digestive juice, play a role in strengthening the spleen and stomach, improve the body's disease resistance; Ginger contains volatile ginger oleone and gingerol, with blood circulation, cold, dehumidification, sweating and other functions; Extract can antagonize type B. Hepatitis virus surface antigen, gingerolone and gingerolone have strong bactericidal effects on a variety of pathogenic bacteria, while gingerols and gingerolone can kill snails or miracidia 100%, and can also inhibit staphylococcus, vaginal trichomonas and dermatophytes.

1 materials and methods

1.1 material

Ginger, distilled water and so on.

1.2 reagents and instruments

Electronic analytical balance, Liangping Instrument Co., Ltd.

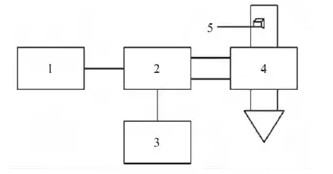

ZM200 ultracentrifugal grinder, Retsch product, Germany; WD800 microwave oven, LG products; high-speed freezing centrifuge, HANNA product, Italy, ginger microwave drying equipment

1.3 test method

1.3.1 sample treatment method

Plan: raw material, cleaning, slicing, microwave drying (stirring).

Grinding, sifting and finished products.

(1) the production of ginger slices. Choose fresh, rot-free, insect-moth-free, non-sprouting ginger, the fiber has not yet hardened and aged, but with the spicy ginger ginger is better than the tender ginger. Trim and remove the handle and pedicle. Rinse thoroughly with water and drain the water. Cut ginger into a uniform ginger slice with a thickness of not more than 3 mm.

(2) production of raw ginger. Take appropriate slices of ginger slices, cut ginger slices into ginger with the same size, the smaller the better.

(3) drying test design. The treated ginger samples were evenly spread on porcelain plates and dried in microwave oven under different microwave treatment conditions.

Hydration capacity (g water / g sample) = (centrifugal tube mass + precipitate mass) - (centrifugal tube mass + sample mass) - Sample quality