Reasons for microwave drying defects of wood

The uniformity of field intensity distribution is also closely related to the drying quality of wood. When the microwave field intensity distribution is not uniform, the temperature distribution in wood is not uniform, especially at the end of drying, the dielectric properties of wood are close to that of dry wood, the relaxation frequency is less than that of microwave. The loss factor increases with the increase of temperature, and has a positive "temperature coefficient", that is, the higher the temperature, the loss of wood. The larger the factors are, the faster the temperature rises, and the higher the temperature rises, the greater the loss factor, which in turn promotes the rise of temperature. Thus, the circulation will cause the "out of control effect" of the temperature in the wood, and in serious cases, the wood will be carbonized, which is not conducive to wood drying.

In summary, microwave drying method itself can not completely avoid the occurrence of drying defects, if the equipment design is unreasonable, drying process control is improper, still may produce cracking, carbonization and other drying defects. Therefore, in order to obtain the ideal drying quality, we still need to consider the microwave drying equipment, drying technology and other aspects, and put forward corresponding solutions to avoid the occurrence of drying defects.

2 precautions against defects in wood microwave drying

From the above theoretical analysis, we can see that there are many factors that affect the microwave drying quality of wood. From the internal factors, there are not only the reasons for the great difference of dielectric properties between different parts of wood caused by the uneven wood properties and water content distribution, but also the reasons of the uneven distribution of electromagnetic field and the limited penetration depth of electromagnetic wave produced by microwave drying equipment. From the external factors, there are many reasons, such as the power of microwave radiation is too large, radiation time is too long, the external air velocity is too fast and so on. Therefore, starting from the above theoretical analysis, the following measures can be taken to prevent the occurrence of drying defects in wood microwave drying.

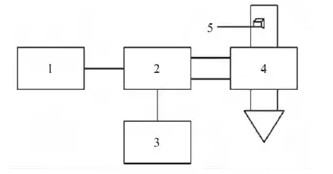

1) In terms of internal factors, the wood microwave dryer, especially the microwave drying chamber, can be optimized to select the appropriate microwave frequency, improve the uniformity of microwave electromagnetic field distribution in the chamber, and improve the monitoring and control system. There are five specific measures: first, choose the appropriate microwave frequency, microwave frequency directly affects the penetration depth of microwave in wood, with the increase of microwave frequency, the penetration depth in wood decreases. Considering that the working frequency of microwave used in industrial microwave heating is generally 915 MHz or 2 450 MHz, and that microwave drying is mainly used for drying hard-dried wood with large thickness, it is suggested that the working frequency of microwave should be 915 MHz in order to improve the wear of microwave in wood when designing and manufacturing wood microwave drying equipment. The penetration depth can improve the homogeneity of microwave heating inside the wood; the second is that the dried wood or the microwave feed inlet is in motion during the drying process, so that the average radiation intensity of each part of the wood is basically equal; the third is that the mode agitator is used in the cavity to periodically change the working mode of the cavity and improve the microwave field. Fourthly, for the microwave dryer whose wood and feed inlet are in a static state during drying process, multiple low power microwave sources can be used instead of a single high power microwave source to improve the uniformity of microwave field. Fifthly, temperature on-line detection, even moisture content on-line detection system is set up in the drying system. The whole drying process of wood is effectively monitored to prevent the temperature inside the wood from exceeding the reasonable control range and to avoid the occurrence of drying defects.

2) In terms of external factors, drying defects can be prevented by strictly controlling drying process parameters, properly prolonging drying time and slowing down drying rate. Theoretically, microwave drying has a very fast drying rate, so long as the power is large enough, the whole drying process of wood can be completed in minutes, or even seconds. However, in the actual wood drying process, due to the structural characteristics of the wood itself, compared with heat transfer, moisture transfer in wood is a relatively slow process. If the power of microwave radiation is too high, the evaporation rate of moisture in wood will be too fast, resulting in high internal pressure, resulting in wood cracking, bursting, and even carbonization defects. Therefore, in the process of drying, the microwave radiation power should be strictly controlled according to the tree species, wood thickness and other factors to avoid drying defects. Secondly, intermittent microwave radiation is used instead of continuous microwave radiation to avoid the occurrence of "hot spots" in wood, and make the moisture and temperature in wood have a self-balancing process. In addition, the velocity of airflow in drying chamber should be controlled. When the air velocity on the wood surface is too fast, the water vapor on the wood surface will be taken away quickly, and the surface shrinkage too fast will easily lead to cracking defects.

The 3 knot theory

Microwave drying, as a relatively new wood drying method rising in the 1970s, has obvious advantages over other wood drying methods in terms of drying quality and drying speed. However, the research and production practice show that microwave drying can not completely avoid the occurrence of wood drying defects, the causes of drying defects and the preventive measures taken are essentially different from other drying methods. In the process of microwave drying, the drying defects are mainly caused by the differences of dielectric properties in different parts of wet wood, the limited penetration depth of microwave, the non-uniform distribution of microwave field intensity and the unreasonable process control. In practical production, trees with erect, elegant, strong resistance and easy management can be used as street trees by optimizing the design of dryers.