Microwave drying characteristics and effects on quality of Litchi chinensis

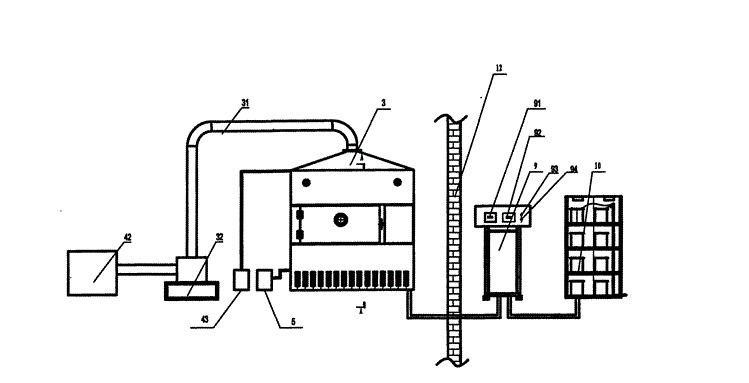

Absrtact: In view of the problems existing in Litchi hot air drying, the effects of microwave drying characteristics and drying conditions on the quality and energy consumption of litchi after drying were studied by using self-made microwave drying equipment test system and intermittent drying process.

The results showed that microwave drying of litchi was mainly in a constant speed stage, and the drying speed depended on different batch ratios; the temperature change could be divided into two stages: rising and stabilizing; the microwave batch time had a significant effect on the quality of litchi after drying, and the drying energy consumption was affected by the batch ratio, but the main influencing factor was heating time.

Key words: Litchi chinensis; microwave drying; drying characteristics; quality

Quote

Litchi is a special fruit in South China. It ripens in high temperature and humidity season. It has high water content and sugar content. It is easy to rot and deteriorate. It is very resistant to storage and transportation. With the rapid development of litchi production, the contradiction between production and marketing has become increasingly prominent, and dried litchi can reduce the losses caused by mildew after harvesting fresh fruit and increase product value. However, the traditional hot air drying has the characteristics of long drying time, high energy consumption and unstable drying quality. It takes 20-25 days for natural drying, 7-10 days for baking and brazing, and tunnel type with air collector.

The greenhouse type drying device needs 6~7 D.

Microwave drying is different from hot air and other drying methods. Because of its unique heating characteristics, fast drying speed, short drying time, high quality after drying and high utilization of heat energy, microwave drying has attracted more and more attention and application in food industry and agricultural products processing.

As early as more than a decade ago, microwave drying of grain (such as rice, wheat, maize, etc.) has been studied abroad. In recent years, microwave drying of fruits and vegetables (fresh fruits, peas, mango, etc.) has been studied. There are also a large number of domestic microwave research reports on rice, rapeseed, fruit and vegetable (such as garlic, onion, preserved fruit, yellow peach, Rosa roxburghii) and other aspects, some of which have been successfully applied and achieved significant economic benefits. However, there is no literature report on microwave drying of litchi, so the author studied the characteristics of microwave drying of litchi, and analyzed the influence of drying conditions on the quality and energy consumption of litchi after drying.