Microwave drying characteristics test of Litchi chinensis

The original average moisture content of fresh litchi fruit after harvest was 79.27% (w.b) by constant temperature box method.

Litchi is a whole fruit with shell drying. In hot air drying, the disadvantageous phenomenon affecting the quality of litchi drying is shell cracking, which is easy to occur within a few hours after the beginning of drying. Due to the heating characteristics of microwave drying equipment, under microwave irradiation, the internal moisture of litchi rapidly vaporizes to form steam pressure, which drives the water to be removed from the litchi.

In the early stage of drying, litchi has a high moisture content, which is a strong driving force and easy to burst the shell, which has been confirmed in the preliminary experiments. In addition, the whole litchi is heated by microwave to form a volume heat source. The temperature of litchi rises rapidly, which can easily cause the loss of sugar and excessive drying of the pulp of litchi.

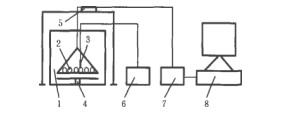

Therefore, in order to ensure the quality of drying, the intermittent drying process was adopted. Each group of experiments took about 425 g of litchi (about 21) and evenly spread on the disc with holes. The quality testing system was started to collect and record data at the beginning of the experiment. Each heating-intermittent period was used to measure and record a group of data, and each group of experiments was repeated twice. During the experiment, the temperature in the control room is about 28 C, the tray is on the microwave oven turntable when heated, the tray is lifted intermittently, and the drying process is carried out to the litchi moisture content of about 30% (w.b).

Conclusion

1) Litchi microwave drying is different from conventional hot air drying. The temperature gradient and heat transfer direction of drying process are consistent with the direction of water migration. The overall drying speed is increased and drying time is shortened. The drying speed of materials in drying process depends on different batch ratios, but heating time plays a leading role.

2) The moisture content of litchi dried by microwave is continuously decreasing, and the temperature changes have experienced two rising and stabilizing stages. The whole drying process can be divided into three stages: acceleration, constant speed and deceleration. The water loss process is mostly in the constant speed stage, and the deceleration period is very short.

3) The main problem affecting the quality of litchi microwave drying is the cracking of fruit shell. The effect of intermittent time on the cracking rate of litchi is the most significant. Therefore, different heating time in the process of litchi microwave drying should have appropriate intermittent time to avoid the occurrence of cracking of litchi shell and reduce energy consumption.