Microwave drying of sesame seeds

Materials and instruments

Zhi Zhi No. 14 white sesame (crude fat content 53.2%, crude protein content)

20.5% Pingyu Kangbo Huixin Oil Co., Ltd. provides absolute ethanol, ether, potassium hydroxide, sodium thiosulfate, glacial acetic acid, isooctane, potassium iodide and other reagents.

MAS-II atmospheric pressure microwave synthesis/extraction reactor; Metrohm 877 potentiometric titrator, 743-Rancimat edible oil oxidation stability tester; 7890A/5975C gas chromatography-mass spectrometry Agilent Technology Co., Ltd; solid-phase microextraction handle, PDMS/DVB extraction head, microwave drying equipment

Factory.

1.2 experimental method

1.2.1 sesame samples are prepared to remove sesame seeds and remove impurities such as sand and dust. In order to simulate the state of newly harvested sesame, 1000 g sesame seeds were sprayed with 140 mL deionized water evenly, sealed in plastic bags and placed in a constant temperature and humidity box at 4 C for 48 hours, shaking evenly every 5 hours, so that the moisture was fully absorbed into the sesame interior, and the reduced sesame samples with moisture content of 11.4% (wet base) were obtained. Spare.

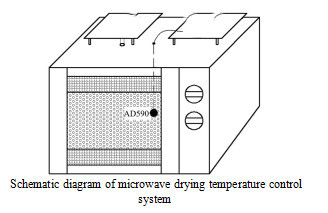

1.2.2 Microwave drying of sesame takes 200 g of sesame sample reduced moisture in 1000 mL three-necked round-bottom flask, puts it into microwave reaction workstation, installs mechanical stirring device and temperature control probe, fixes flask, carries out drying experiment, and determines moisture content at set time (0, 10, 20, 30, 40, 50 minutes), 0, 3, 5, 1. 0, 15, 20, 25, 30 minutes to determine the germination rate) and temperature (60, 65, 70, 75, 80, 85, 90 C) take out immediately placed in the dryer, stand by.

1.2.3 Sesame oil is produced by hydraulic method: microwave dried sesame is packed into filter bag, put into the chamber of hydraulic press, and make oil at room temperature. The chamber pressure gradually rises to 50-60 MPa. Sesame oil is pressed repeatedly for 4 times to obtain the pressed sesame oil.

1.2.4 The main indexes of sesame and sesame oil were determined by GB/T 14489.1-2008, the germination rate of sesame seeds by GB 5520-1985, the acid value of sesame oil by GB/T 5530-2005, and the peroxide value of sesame oil by GB/T 5538-2008.

Determination of oxidative stability of sesame oil: weigh 5.0 g sesame oil, 10 L/h air flow rate, determine the reaction time corresponding to the maximum second derivative of conductivity of oil sample at 120 (?) C, i.e. induction time, through induction time to reflect the oxidative stability of oil.

1.2.5 The volatile components of sesame dried by microwave were enriched by headspace-solid phase microextraction (HS-SPME). The sesame dried by microwave was placed in a 15 mL headspace bottle, sealed with a silica gel pad lined with polytetrafluoroethylene (PTFE). The sesame was adsorbed in a constant temperature water bath pot at 60 (?) for 20 minutes and then balanced. The active extraction head was inserted to enrich the odor components for 30 minutes, and then the extraction head was inserted into the sample inlet of the GC-MS. The sample was analyzed for 5 minutes under the non-shunt mode at 240 C.

1.2.6 Gas Chromatography-Mass Spectrometry (GC-MS) Determination Conditions Chromatographic Conditions: Chromatographic Column HP-5MS Phenyl Methyl Silox (30 m x 250 um x 0.25 um), Inlet Temperature 240 C, Programmed Temperature (initial temperature 35 C, 8 min, then 5 C/min to 230 C, 10 min), Carrier Gas for High Pure Helium, Flow Velocity 1 mL/min, no diversion

Enter the sample.

Mass Spectrometry Conditions: Ion Source Temperature 230 C, Fourth Stage Rod Temperature 150 C, Auxiliary Heater Temperature 250 C; Ionization Mode is Electron Bombardment Ionization

(Electron Impact, EI), the electron energy is 70 eV; the full scan quality parameter 30~550 u. NIST 08.LIB mass spectrometry library was used to qualitatively analyze the detected flavor substances. The components with matching degree higher than 800 (maximum value is 1000) were analyzed. The relative content of each component was calculated by peak area normalization method.

3 conclusion

Sesame seeds were dried at different drying temperatures and times by temperature-controlled microwave dryer. The higher the drying temperature in the experimental range, the shorter the time required to reach the same moisture content. The moisture content of sesame seeds dropped rapidly within the first 20 minutes of drying. The moisture content of sesame seeds decreased 81% at the drying temperature of 90%. High temperature and long time microwave drying had a significant destructive effect on the vitality of sesame. After microwave drying for more than 20 minutes, all treated sesame had lost germination ability. During drying time of 20 min, the temperature corresponding to the drying temperature increases when the temperature is below 80 C.

The acid value and peroxide value of sesame oil changed little, at 80 degrees centigrade.

The acid value and peroxide value of sesame oil increased significantly; the main volatile components of sesame were alkanes, aldehydes, alcohols, alkenes, naphthalenes, esters and phenols; with the increase of drying temperature, the contents of alkanes, naphthalenes and phenols decreased, aldehydes increased, and the number of volatile components decreased, 38, 35 and 31, respectively. According to the effect of microwave drying on the quality of sesame, the optimum drying conditions for non-species sesame are that the temperature is lower than 80 C and the drying time is less than 20 min. Microwave drying instead of traditional drying method.

Sesame non seed drying provides an effective drying method and has broad application prospects.

报错