Microwave drying and its development

[Abstract] The principle and characteristics of microwave drying equipment and the basic composition of microwave drying system were analyzed. At the same time, the application of microwave drying equipment in agricultural products drying was predicted and analyzed.

[Key words] drying; microwave; microwave drying of agricultural products.

1 Fundamentals of microwave drying

1.1 principle of microwave heating

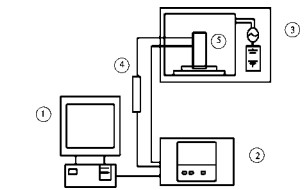

Microwave refers to electromagnetic waves with penetrating characteristics in the wavelength range of 1 m~1 m and frequency range of 3.0*102~3.0*105 MHz. The commonly used microwave frequencies are 915 MHz and 2 450 MHz. The magnetron of the microwave generator receives power from the power supply and generates microwave power, which is transmitted to the microwave heater through the waveguide. The materials that need to be heated are heated under the action of microwave field.

Microwave heating utilizes the principle of dielectric loss, and the loss factor of water is much larger than that of dry matter. Most of the energy released by electromagnetic field is absorbed by water molecules in the material. Generally speaking, due to Brownian motion, the arrangement of water molecules in dried materials is disorderly and rapidly changing. Polarity counteracts each other and does not show polarity on the macro level. When placed in the electric field generated by the microwave generator, the microwave field changes the direction of the applied electric field at a high speed of several hundred million times per second, which makes the polar water molecule of the medium swing rapidly and produces a significant thermal effect, so that the temperature inside and on the surface of the material rises rapidly at the same time.

1.2 mechanism analysis of microwave drying

Microwave heating results in the existence of heat source of material body, which changes the gradient direction of some migration potential and migration potential during conventional heating drying process, and forms the unique mechanism of microwave drying.

Because of the large loss of water medium in the material, which can absorb a large amount of microwave energy and convert it into heat energy, the heating and evaporation of the material are carried out simultaneously in the whole body. On the surface of material, due to evaporative cooling, the surface temperature of material is slightly lower than that of the inner layer. At the same time, because of the heat generated inside the material, the internal steam is generated rapidly, forming a pressure gradient.

If the initial moisture content of the material is very high and the pressure inside the material increases very quickly, the moisture may be removed from the material under the action of pressure gradient. The higher the initial moisture content, the greater the influence of pressure gradient on water removal, that is to say, there is a "pump" effect, which drives water to the surface and speeds up drying. It can be seen that the temperature gradient, heat transfer and vapor pressure migration directions are the same in the microwave drying process, which greatly improves the moisture migration conditions in the drying process, of course, better than conventional drying. At the same time, due to the existence of pressure migration power, microwave drying has the characteristics of drying from inside to outside, that is to say, the inner layer of material will be dried first, which overcomes the shortcomings of the hard shell formed by the outer layer of material drying first in conventional drying, which prevents the internal moisture from continuing to move out.