Optimization of Microwave Drying of Non-fried Instant Oysters by Response Surface Methodology

Abstract: The effects of microwave drying equipment on the sensory quality of non-fried ready-to-eat oyster products were studied by using Box-Behnken Design and response surface analysis. The results showed that the microwave drying equipment required for non-fried instant oysters was the most The optimum process parameters are microwave power 300 W, microwave drying time 60 s, hot air drying temperature 60 °C, hot air drying time 60 min.

After Microwave drying oysters, the ready-to-eat oyster products are bright in color, moderate in hardness, and have a certain chewyness and full appearance. The development of ready-to-eat aquatic products can meet people's demand for aquatic products and enrich people's dietary structure. As a high-protein, low-fat aquatic product, oysters are delicious and nutritious, and are known as "milk in the sea."

In addition, oysters are rich in vitamins and minerals, especially trace elements such as zinc, selenium and iodine (the amount of iodine is 200 times higher than that of cow's milk). As an important marine shellfish resource, oysters are abundant in coastal countries around the world. Therefore, based on its good edible value and economic value, oysters are more and more popular, and the development and application prospects are broad.

In the early European and American countries, the use of oysters was mainly based on food, while in addition to direct consumption, Japan also developed oyster health food. In recent years, with the rapid development of modern biotechnology and food processing technology in the United States, Europe, Japan and other countries, liquid, tablet and capsule functional foods using oysters have appeared in large quantities.

There are few reports on the development of oyster products in China. Oyster products are mainly sold in fresh produce. Oyster processed products are mainly non-ready-dried products, and a small amount is processed into emu oil or other condiments. Therefore, oyster deep processing products have not been developed as they should.

As one of the four major oyster producing areas in China, Guangxi is rich in oyster resources. However, like the oyster processing industry in other parts of the country, the Panbei Bay oyster industry processing technology is backward and the added value of products is very low. This is the extension and upgrading of the oyster breeding industry chain. The main bottleneck. In order to further meet the consumer demand for ready-to-eat oyster products, increase the added value of oyster products, and use scientific methods to extend the shelf life of oysters, it has become the key to the development of oyster industry.

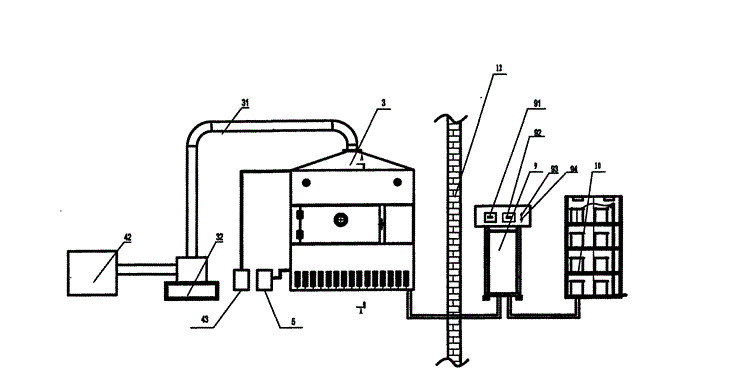

Market research and related data show that there are no oyster non-fried instant products in China's market. In the processing of ready-to-eat products, the optimization and improvement of the drying process is the focus of the entire production process. The drying methods commonly used in Chinese enterprises are hot air drying and microwave drying. The traditional hot air drying method has wide application, low equipment investment, strong adaptability and simple operation control, but low drying efficiency and long time have adverse effects on the sensory quality of the product.

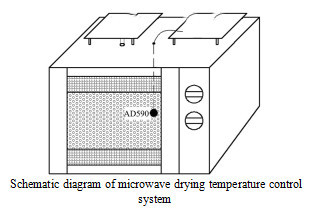

Microwave drying is a new drying technology that has developed rapidly in recent years. It has the advantages of high speed, high thermal efficiency and no pollution. However, due to the shape of the material, it may form a sharp angle effect and affect the quality of the product. Many scholars use microwave-hot air combined drying method to dry food, and the effect is good. However, the effect of microwave-hot air combined drying on the sensory quality of ready-to-eat oysters has not been directly reported at home and abroad, and is still under research and evaluation.

Therefore, this study intends to study the effects of combined drying on the sensory quality of ready-to-eat oyster products through response surface test, and give the optimal conditions for joint drying, in order to provide a theoretical basis for the development and application of ready-to-eat oyster products.