Drying Status and Technology Optimization of Xinjiang Walnut

Abstract: Drying plays an important role in postharvest processing, storage and transportation of walnut. This article specifically describes the current Xinjiang walnut dry

The current situation and existing problems of microwave drying equipment, and the corresponding technical analysis and optimization for these problems, put forward the main walnut varieties for our district, combined with the local environment, mainly hot air drying, research a variety of drying techniques combined The combined drying technology is one of the main research directions in the future.

Key words: walnut microwave drying; drying technology; research status; technology optimization

Walnut, also known as walnut, is one of the world's four major dried fruits, and is also an important part of China's important fruit industry production. As a big walnut producing country, China's planting area and output rank first in the world. The main cultivation areas of walnuts in China are Yungui, Northwest and North China.

Among them, Xinjiang is one of the main production areas of walnuts, and many counties and towns have walnut distribution. Xinjiang, especially in southern Xinjiang, has long illumination time, high effective accumulated temperature, large temperature difference between day and night, less rain during growing season, and dry air, which is beneficial to fruit ripening and inhibits pest and disease breeding. It has suitable climatic conditions for walnut growth and development, and good ventilation and water permeability. The cultivation conditions of the soil and irrigation water supply facilities, as well as the industrial policy of developing walnuts, have the unique advantages of the development of the walnut industry.

Xinjiang walnut production areas are mainly distributed in the Aksu area, Hotan area and Kashgar area. In recent years, with the improvement of the technical level, the annual output of Xinjiang nuclear peach has greatly increased. However, due to the concentrated harvest time, the fresh walnuts after harvesting cannot be treated in time, often causing mildew, which brings great economic losses to farmers.

The drying treatment of walnut is one of the important links in the processing of walnut fruit after harvesting. It is essential for the nutrient preservation, color and subsequent value mining of walnut. The drying process of walnuts is accompanied by a large amount of energy consumption and high labor and material costs. Therefore, how to choose the appropriate walnut drying process is a key issue for farmers.

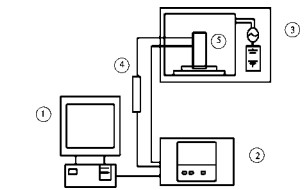

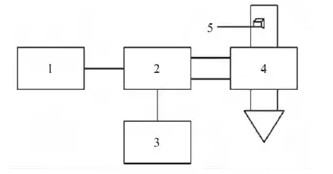

Microwave drying is performed by using electromagnetic waves that have a wavelength range of 1 to 1 000 mm and a frequency range of 3 × 102 to 3 × 105 MHz. When microwave heating, the magnetron of the microwave generator receives the power of the power source to generate microwave power, and is sent to the microwave heater through the waveguide, so that the material to be heated is heated under the action of the microwave field, due to the loss factor ratio of water in the material. The dry matter is much larger. Most of the energy released by the electromagnetic field is absorbed by the water molecules in the material. The microwave field periodically changes the direction of the applied electric field at a high speed of several hundred million times per second to make the polar water molecules of the medium in the material. Quickly oscillates, producing significant thermal effects for dryness.

Compared with traditional drying technology, the new drying technology has the characteristics of faster efficiency, better product quality and higher standardization, which can further tap the added value of dried walnut products. However, the new drying technology greatly improves the drying efficiency and reduces the labor consumption, but the application of high technology brings more energy loss and demand than the traditional drying technology. How to comprehensively consider the balance between energy consumption, production cost of human consumption, drying rate and drying quality is a question worth pondering.