Research on lotus leaf drying process

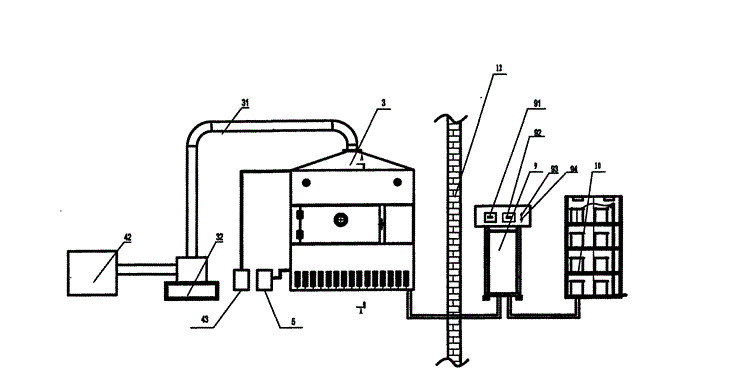

Abstract: In order to determine the best drying method and process parameters of the lotus leaf, freshly stalked lotus leaves are used as raw materials. The lotus leaves are first cleaned, graded, cut and steamed, and then steamed. Secondly, microwaves with different powers are used. Treatment to improve its drying quality; Finally, the "microwave-blast drying" process of lotus leaf tea was studied by single factor and orthogonal experiment.

After testing, it was found that steam was used. 5 min, microwave fire strength 60%, microwave drying equipment processing time is 60 s, lotus leaf tile thickness is 2. 5 cm, the blast drying temperature is 70 °C, and the blast drying time is 0. At 5 h, the obtained lotus leaf quality is better.

Key words: lotus leaf microwave drying; blast drying; process

In the No. 45 document of Wei Jian Fa (1991) of the Ministry of Health, the lotus leaf was included in the second list of “food and medicine”. Lotus leaves have the functions of lowering blood fat, quenching thirst and dampness, strengthening spleen and sun, inhibiting fat, inhibiting bacteria, and dispersing silt. The lotus leaf contains caffeine, original lotus leaf, lotus leaf and a variety of alkaloids, vitamin C and other active substances and aroma components, which can be used for the prevention of weight loss and hypertension and cerebrovascular diseases.

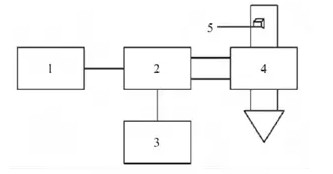

Common lotus leaf drying methods include blast drying, microwave drying and vacuum freeze drying. Previous studies have focused on the study of single drying mode of lotus leaves, while the research of lotus leaf drying process by composite method is less. In this paper, the application of microwave--blast composite drying method in the process of lotus leaf drying is studied to provide a reference for further improving the quality of dried lotus leaf products.

The most suitable microwave-blast drying conditions for lotus leaves are: first microwave treatment, microwave fire strength is 60%, treatment time is 60 s; then blast drying, hot air temperature is set to 70 °C, lotus leaf thickness For 2. 0 cm, drying time is 0. 5 h, under these conditions, the lotus leaf obtained has a good aroma, fresh and even yellow-green, mellow aroma, fresh and mellow taste.