Effect of Drying Method on Edible Jujube Edible and Nutritional Quality

Abstract: The edible and nutritional quality of fresh dried jujubes by microwave drying equipment, microwave vacuum expansion, vacuum freeze drying and medium-short wave infrared drying were analyzed to determine the effect of drying methods on the nutritional characteristics of fresh jujube.

The results showed that the dry processing significantly increased the total sugar and reducing sugar content of fresh jujube (P<0.05). In addition to the short-wave infrared drying, the total acid content after drying was significantly reduced (P<0.05), and the product browning was low. The ratio of sugar to acid was obviously improved; the retention rate of VC by microwave vacuum freeze-drying was as high as 98.62%; the total phenolic content was significantly increased after microwave vacuum expansion and microwave vacuum freeze-drying (P<0.05), which was 4 721.30 mg/100 g (dry The mass spectrometer, the same as below) and 4 516.25 mg/100 g; the flavonoid content increased to 80.51 mg/100 g after vacuum freeze-drying.

In terms of microstructure, vacuum freeze-dried fresh jujube is dense and porous, and it is honeycomb-shaped; microwave vacuum freeze-drying fresh jujube pores are uniform; microwave vacuum puffing fresh jujube structure is loose, many small molecular particles; medium and short wave infrared dry fresh jujube Solid and dense, no cavity structure. In terms of sensory evaluation, the comprehensive evaluation of the color, aroma, taste and shape of fresh jujube by microwave vacuum freeze drying and microwave vacuum puffing is close to vacuum freeze drying. On the whole, microwave vacuum freeze-drying and microwave vacuum puffing have significant advantages in processing fresh jujube, and the efficiency is high and the cost is low, and the application prospect is broad.

Key words: microwave drying jujube; microwave vacuum puffing; medium and short wave infrared; vacuum freeze drying; nutritional quality

Dongzao is an important fresh jujube variety of red dates. The fresh winter jujube is thin, crisp, sweet and delicious. Fresh jujube has a very high water content and is perishable in a short time after harvest, which affects its commodity value. Therefore, in addition to fresh food, in order to better preserve and extend the shelf life of fresh jujube, the processing method of jujube products is crucial. .

At present, dry processing is the main primary processing method for fresh jujube. More than 80% of jujube fruit in China is processed and dried. Different drying techniques will affect the edible and nutritional quality of jujube. With the continuous excavation of functional ingredients of fresh jujube and the awareness of consumers' health care, the changes of nutrients in jujube fruits after drying and the influence of drying process on their physiological active substances have gradually become the focus of consumers.

Natural drying and hot air drying are widely used and most traditional methods of fresh jujube drying, but they take a long time and high temperature, which is easy to cause loss of color, nutrition and functional ingredients of fresh jujube, and the appearance of dry products is also extremely It is easy to change and does not meet the consumer's requirements for “nutritional, safe and palatable” food.

In recent years, modern processing companies have gradually broken the traditional single dry mode and turned to dry processing such as microwave drying and vacuum freeze drying, which not only can obtain high-quality products, but also efficiently retain phenolic compounds in jujube fruits. In the actual processing process, there is still a certain resistance affecting the continuous production of fresh jujube. For example, freeze-drying induces the internal water sublimation of jujube fruit and maintains a high vacuum state, which requires huge energy consumption; infrared drying and heat preservation requirements are strict, and the cost is high; Microwave drying has large investment and unstable signals, so improving drying efficiency and reducing energy consumption have become the ideal way for modern enterprises.

Microwave vacuum expansion combined with microwave heating transient and vacuum drying low temperature, high speed and high efficiency; microwave vacuum freeze drying, is a combination of freeze drying and microwave vacuum drying green new fruit and vegetable drying technology, with high quality, high efficiency With low energy consumption, this technology has been successfully applied in the processing of dried apple chips, mushroom chips and mango slices, and has gradually become a research and development hotspot. In China, although some scholars have studied the effects of different drying methods on the quality characteristics of fresh jujube, they are concentrated in several common drying techniques. The relevant reports on the effects of the above new drying technologies on the quality of fresh jujube are still rare.

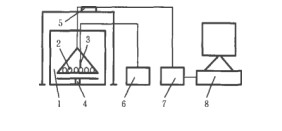

To this end, this study used modern medium-short-wave infrared drying, vacuum freeze-drying, new microwave vacuum freeze-drying, microwave vacuum puffing drying method to dry the fresh jujube, and compare the main nutrients of fresh jujube with different drying techniques. The influence of flavor substances is aimed at providing a theoretical basis for the processing of fresh dried jujube products, and providing new ideas for enriching the consumer market and promoting the upgrading of high-quality fresh jujube products.