Temperature and moisture distribution model of microwave dried active rice

Abstract: The temperature and water content distribution in the microwave drying equipment of active rice was obtained by establishing the mass heat transfer model of continuous microwave drying active rice process, and the microwave intensity was 1 . 16, 2 . 75, 4 . Under the condition of 34 W / g, the experimental verification of the active rice temperature and moisture model was carried out to determine the correctness of the heat and mass transfer model.

The simulation and measured results show that: in the dry end of the continuous microwave dryer, when the temperature rises slowly, the microwave power is controlled accordingly, and the energy consumption of microwave drying is reduced. After the drying section, the temperature is reached, so that the temperature inside and outside the active rice material reaches Balance, the drying effect is more uniform, and the dry quality can be guaranteed. This study has guiding significance for the microwave heating process and control of reactive rice.

Key words: active rice microwave drying; temperature; moisture

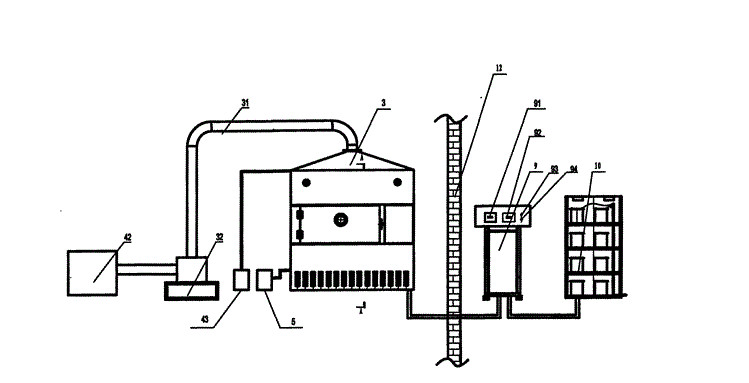

The continuous microwave machine is used to dry the active rice. The temperature and moisture distribution and change of the material affect its drying efficiency and quality. It is the main indicator for controlling the drying process of the microwave dryer control system.

Most of the existing microwave drying processes focus on the microwave drying characteristics of the material and the temperature and moisture changes depending on the drying time; while the continuous microwave dryer enters the normal operation process along the direction of the conveyor belt movement in the dryer, The temperature and moisture of the material can be regarded as changing only with position and not changing with time, which is a steady state process.

According to the microwave drying characteristics of the active rice, the temperature and moisture steady-state distribution model of the active rice in the microwave dryer is established, which is helpful to analyze the change trend of the material temperature rise and the water drop. It is a continuous microwave dryer designed to dry the active rice. Important reference.

In this paper, the variation law of temperature and water content in microwave drying process is studied. The law of drying process temperature and water content changes with distance is derived by theoretical formula, and the theoretical model is verified by experiments.

According to the simulation results, on the continuous microwave dryer, along the direction of the material conveyor belt movement, it can be inferred that the first low ( 1. 16 W / g) rear high ( 2. 75W / g) microwave intensity input method is beneficial to improve Utilization of microwave energy.

Based on the optimal process parameters obtained in the drying test, the mass heat transfer model of the continuous microwave drying active rice process is established, and the temperature and water content distribution in the active rice microwave dryer can be obtained, and the microwave intensity is 1. 16, 2. 75, 4. Under the condition of 34W / g, the experimental verification of the active rice temperature and moisture model was carried out to determine the correctness of the heat and mass transfer model.

The simulation and measured results show that: in the dry end of the continuous microwave dryer, when the temperature rises slowly, the microwave power is controlled accordingly, which can reduce the energy consumption of microwave drying and improve the drying quality. Continuous microwave drying should enter the slow-slowing stage after the drying section to balance the temperature inside and outside the active rice material, so that the drying effect is more uniform and the drying quality can be ensured.