Study on Process Conditions of Processing Grass Pine by Microwave Drying Method

Abstract: The grass carp is used as raw material to process grass carp pine by microwave drying equipment. The sensory score of grass carp pine was used as the main evaluation index to investigate the effects of cooking time, microwave drying power, microwave drying time, frying time and pulverization frequency on the quality of grass carp pine during the processing of grass carp pine, and the grass carp pine was tested by orthogonal test. The processing parameters are optimized.

The results showed that the processing conditions of grass carp were: cooking time 20 min, microwave drying power 500 W, microwave drying time 6 min, frying time 12 min, pulverization times 5 times (5 s / time). Under the optimal conditions, the grass carp had a moisture content of 15%, a protein content of 51.8%, a fat content of 8.7%, and an ash content of 1.1%.

Key words: grass carp microwave drying; fluffy pine; process optimization; microwave drying

Grass carp (Ctenopharyngodon idella) is an important freshwater economic fish in China. In 2014, the output of grass carp in China was 5.377 million tons, which is the largest variety of aquaculture products. The grass carp is tender and not greasy, has less intermuscular thorns and is rich in nutrients. It is very popular among consumers. However, grass carp is still mainly sold fresh, with fewer processed products and low added value. With the increasing scale and output of freshwater aquaculture in China, the problem of processing grass carp needs to be solved.

Flossy meat is a fluffy or granulated meat product made from the process of trimming, dicing, boiling, simmering, seasoning, collecting soup, frying pine, and pine. The content is low, and the water activity is generally between 0.7 and 0.75, which can effectively inhibit the growth of bacteria, mold and yeast. Floss is a famous specialty in China. It is rich in nutrients, delicious and delicious, and easy to carry. Pork pine, beef pine, chicken pine, fish pine and egg pine are good foods for food, gifts and tourism.

In the traditional meat pine production process, the process of collecting juice after cooking is time-consuming, and the process conditions are not easy to control. If the re-cooking soup is insufficient, the cooking is not transparent, which brings difficulties to the pine; if the soup is too much, the juice is collected. Excessive cooking, so that the finished fiber is short.

In addition, after the boiling of the juice is finished, the dewatering is completely completed by frying, which is time-consuming and labor-intensive, and has low production efficiency and cannot meet the requirements of industrial production. The process of collecting and frying the pine after cooking is a key step in the production of the meat, which has a great influence on the quality and production efficiency of the final product.

In the research on the improvement of the processing technology of the fleshy pine, the treatment without the juice and the direct drying after the boiled can greatly simplify the process, and the flavor of the product is also well maintained. In the frying and drying process, the “segment-balance” dehydration using an oven or other dewatering equipment is beneficial to the improvement of the meat quality and the shortening of the production cycle.

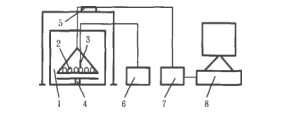

At present, the market selling fleshy pine is mainly pork pine and beef pine, and the fish pine is still relatively small. The grass carp is used as the main raw material to develop grass carp pine, and the microwave drying method is used to replace the traditional method of drying the meat. The process and process parameters of the production of grass carp, in order to provide reference for the deep processing of grass carp.