Effect of Microwave Drying Condition on the Content of Maize Pepper and Its Process Optimization

Abstract The microwave drying equipment was optimized by the response surface method using fresh “Jiuyeqing” green pepper which was steam-killed. Taking microwave power, deposition amount and microwave time as independent variables, the effects of microwave power on the content of numbness of green pepper were studied.

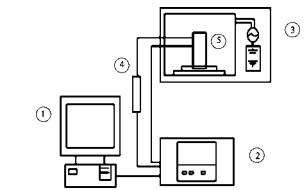

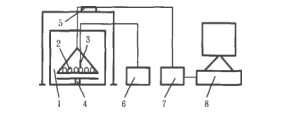

Through a single factor test, determine the appropriate range of influence. On the basis of the single factor test, the content of the numbing substance is used as the response value, and the optimal experimental design is carried out according to the Box-Behnken Center combination test design principle; Design-Expert. V 8. 0. 6 software, establish a microwave drying regression model, and optimize the index of microwave drying green pepper by setting the maximum content of the numbing substance.

The results showed that the optimization condition of the microwave drying index of the green pepper was microwave power 357. 78 W, the amount of placement 203. 38 g, microwave time 49. 14 s, under these conditions, the content of numbing substance 24. 328 7 mg / g; and the verification experiment under optimized conditions, the error between the verification result and the optimization result is 1. 18%, the optimization results are reliable.

Key words: fresh blue pepper microwave drying; response surface method; hemp substance; process optimization

Zanthoxylum L. is a plant of the genus Zanthoxylum L. native to China and has about 250 species. Zanthoxylum bungeanum has the effects of dispelling insects and relieving itching, relieving pain in the middle and relieving dehumidification. The pepper numbness has the functions of anesthesia, analgesia, blood fat reduction, gastrointestinal protection, etc., and has physiological activities such as anti-cancer, anti-oxidation and wrinkle removal. However, the harvest of green pepper is seasonal and it is not resistant to storage, while dried green pepper has a positive impact on prolonged storage. Therefore, dried pepper has an important role in the pepper industry.

At present, the drying of pepper is mainly dry such as natural drying. Natural drying does not require investment, low cost, and is not limited by the site, but it is susceptible to weather conditions. The research on the drying of pepper is hot air drying, microwave drying, microwave vacuum drying, etc. Microwave drying has the characteristics of uniform heating, high speed, high efficiency and easy industrialization and application. It has application value in the industrial drying production of pepper and is gradually applied. in.

In the microwave drying research of pepper, mainly focused on the mathematical model and microwave drying characteristics, the quality is mainly the external quality and the effect of chlorophyll content. The influence of the content of the peppery material in microwave drying conditions has not been reported yet, but the pepper The content of numbness is an important quality indicator of dried pepper. Therefore, the microwave drying test on the green pepper was carried out to study the effects of different microwave drying conditions on the content of the peppery material, and the optimization experiment was carried out, which is of great significance for improving the quality of dried pepper and the industrialization of the microwave drying technology of pepper. The application provides a certain theoretical basis.