Microwave drying wood application equipment

Drying the wood to achieve a certain moisture content is an important means to ensure the quality of the wood products, so dry before use. Currently, it is generally heated by hot air microwave drying equipment, this method, regardless of its heat source mode, uses hot air to heat the wood from the outside to evaporate its surface water to form a surface and internal moisture gradient, which promotes the diffusion of moisture from the inside to the outside to achieve the purpose of drying wood.

If the surface evaporation rate is balanced with the internal diffusion rate, the wood is heated evenly, the temperature and humidity are appropriate, and the wood can be dried quickly. Therefore, in order to suppress the initial surface moisture diffusion when drying the wood, the high temperature and high humidity method should be used to increase the thermal conductivity. However, this method is difficult to achieve due to the poor thermal conductivity of the wood itself.

Microwave wood drying characteristics

The moisture in the wood is discharged from the inside to the outside at the same time, so that the expansion and contraction coefficient of the wood is basically the same, which can maximize the loss of deformation, cracking, dryness, carbonization and the like in the drying process, and can significantly improve the wood yield. .

The original color of the wood can be maintained. The microwave drying of the wood does not change the original color of the wood. When the wood is dried by other conventional heating methods, the color is deepened, and some become yellow and black, which lowers the grade of the wood product. The reason, the price can be several times different.

Microwave-dried wood can completely remove the internal stress of the wood, and the finished wood products will not be deformed or cracked, which can improve the quality of the wood products. Microwave drying is selective when the wood is high. The part with high water content absorbs more microwave energy and gets more heat. This is conducive to the uniformity of wood moisture content.

The wood microwave drying equipment is the overall heat generation of the wood itself, no thermal inertia, no heat transmission loss, and the drying speed is more than 10 times faster than the traditional heating method.

Microwave drying of wood can completely kill various insects and eliminate wood pests.

Microwave drying of wood does not require soaking, cooking, steaming and other process streams.

The biggest feature of wood microwave drying equipment is the semi-finished products of dry wood products. Since ancient times, the process of fine-graining is to dry the wood before using it. If it is first cut and then dried, the formed wood will crack slightly during the drying process. Deformation, you can't use it.

The microwave directly formed by the wood can keep the wood as it is, without deformation, without cracking or damaging the wood. Therefore, the plates and square materials can be made into semi-finished products of various shapes and specifications according to the needs of the wood product structure. The pillars can be lighted first, and then enter the microwave drying oven. The unused materials such as corners in the fine wood production account for about 40% of the used materials. After the semi-finished products are made, the dried materials can save these unused materials. Dry energy.

In addition, the first drying and then drying will make the original defects in the wood no longer expand, which can increase the utilization rate of wood by 15% and 20%, save a lot of wood and energy, and its economic benefits are very significant.

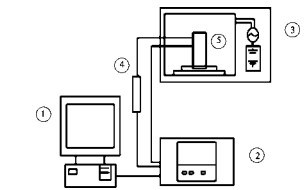

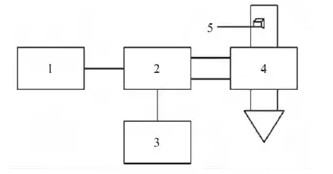

Since the microwave drying wood equipment is easy to realize automatic control, the drying time can generally be determined according to several parameters. The drying time can be set only during the operation, no need for personnel to wait, the wood drying will automatically stop, and the microwave drying wood It is simple and convenient, and it is free from environmental pollution.