Microwave Processing Pu'er Tea Technology and Equipment Research

Abstract: In view of the rapid development of Pu'er tea processing industry, the mechanism of processing Pu'er tea by microwave drying equipment and the application of microwave technology in the killing and drying of Pu'er tea are discussed, and the microwave production for processing Pu'er tea is also discussed. The equipment proposed design ideas and methods.

Key words : microwave drying Pu'er tea; microwave curing

Pu'er tea is a special tea variety in Yunnan Province. It is well known both at home and abroad for its unique taste and various health care and pharmacological functions. However, most tea manufacturers still use traditional processing techniques, namely coking coal gas baking, steam dehydration and sun exposure. The drying method causes the finished product to be harmful, the microbial and bacteria are not completely eliminated, and it is difficult to meet the internationally prescribed standards, which seriously affects the market competitiveness of Pu'er tea and earns foreign exchange through exports.

At present, Yunnan Pu'er tea industry basically presents the characteristics of “market first, lagging research and development, incomplete standards, backward technology”. In response to the demand for Yunnan Pu'er tea production, we should take science and technology as the guide, actively improve traditional tea processing technology and improve processing technology. Technology is a high-efficiency, energy-saving and environmentally-friendly modern processing technology. The application of microwave energy to Pu'er tea will create a new processing route for Pu'er tea industry.

Mechanism of microwave drying materials

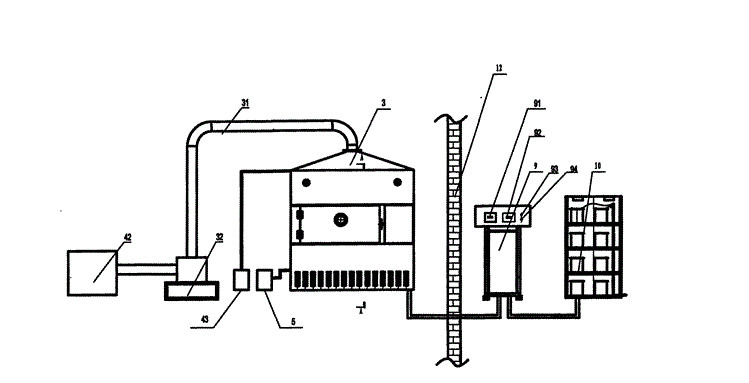

The magnetron of the microwave generator receives the power of the power source to generate microwave power, and is sent to the microwave heater through the waveguide, so that the material to be heated is heated under the action of the microwave field, and the microwave heating utilizes the principle of dielectric loss, water loss. The factor is much larger than the dry matter, and most of the energy released by the electromagnetic field is absorbed by the water molecules in the material.

Under normal circumstances, the water molecules in the material are disordered by Brownian motion, the polarities are mutually offset, the polarities are not mutually polarized, and when placed in an electromagnetic field generated by a microwave generator, the microwave field is several times per second. The high-speed period of hundreds of times changes the direction of the applied electric field periodically, so that the polar water molecules of the medium oscillate rapidly, thereby generating frictional heat, which causes the temperature inside and outside the material to rise rapidly.

Microwave heating makes the material itself a heat source. Since the moisture in the material can absorb microwave energy and convert it into heat energy, the temperature rise and evaporation of the material are simultaneously carried out in the whole object, which changes some migration potential in the conventional heating and drying process. And the direction of the migration potential gradient forms a unique mechanism for microwave drying materials. The surface temperature of the material is slightly lower than the temperature of the inner layer due to evaporative cooling. At the same time, due to the heat generated inside the material, the internal steam is rapidly generated, forming pressure. Gradient. If the initial moisture content of the material is high and the pressure inside the material rises rapidly, the moisture may be discharged from the material under the action of a pressure gradient.

It can be seen that during the microwave drying of Pu'er tea, the temperature gradient, heat transfer and vapor pressure migration direction are the same, which greatly improves the moisture migration condition during the drying process. At the same time, due to the existence of pressure migration power, the microwave drying has an inward direction. The external drying characteristics, that is, the first layer of the material is first dried, which overcomes the shortcomings of the conventional method of drying the material due to the outer layer drying to form a hard shell knot and hindering the internal moisture from moving outward.