Discussion on microwave drying of cereals

Abstract: Microwave drying equipment has been applied in many fields because of its high efficiency, energy saving and environmental protection requirements. However, microwave drying cereals are still in the exploration stage. The mechanism and equipment of microwave drying were briefly introduced. The characteristics of microwave drying were summarized. The research progress of microwave drying grain was introduced and the research direction was put forward.

Keywords: microwave drying grain

In recent decades, China has made great progress in the research and development of grain drying technology and equipment. However, with the increase of energy shortage, the disadvantages of energy consumption in China's grain drying equipment are becoming more and more prominent, exploring new types of low-energy grain drying. Technology seems imperative.

At present, research on biomass fuel, solar energy drying, and infrared drying are actively carried out. Microwave drying is a new type of drying technology developed in recent decades. It has been widely used in food, chemical, metallurgical and other fields, but research in the field of domestic grain drying is still in its infancy. Microwave drying has the advantages of high speed, high efficiency and low energy consumption. Therefore, actively exploring the microwave drying of cereals and in-depth study of the application forms of microwaves in grain drying will have broad prospects and practical significance.

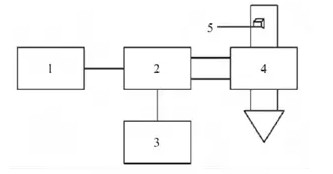

Introduction to microwave drying mechanism

The microwave is a high-frequency electromagnetic wave having a wavelength of 0.001 m to 1 m and a frequency of between 3.0 x 102 and 3.0 x 105 MHz. In reality, the grain material is mainly composed of polar molecules. In the microwave field, due to the charge “same-rejection, opposite-sex attraction”, the molecules will produce corresponding movements, and its vigorous movement promotes interaction between molecules. Thus, the thermal motion of the molecule is intensified, and the macroscopically appears to be an increase in the temperature of the material.

As the external microwave frequency increases and the electric field strength increases, the thermal motion of the molecules will also increase and the temperature of the material will become higher. For a given medium or material, the power absorbed by the medium is proportional to the power supply frequency and electric field strength. Since the material is internally heated in the microwave field, it is easy to form a temperature gradient and a humidity gradient in the same direction, so that the two moisture driving forces are in the same direction, which is favorable for the material moisture to be discharged outward.

After several decades of development, microwave drying technology has been used more and more in the production field, but microwave drying grain technology is still in the stage of continuous exploration, and there are many technical and economic problems to be solved. Microwave drying technology will be combined with other drying technologies while improving its own technical methods and equipment, such as microwave hot air combined dry grain, microwave infrared dry grain, using the advantages of various drying processes to different in different drying stages of materials. Drying process to achieve high efficiency, low consumption and high quality drying effect.