Current status and prospects of processing and processing of honeysuckle

Abstract: Drying is an important part of the quality of honeysuckle products. This paper summarizes the advanced drying technology at home and abroad, and analyzes the advantages and limitations of traditional drying methods such as hot air drying, microwave drying equipment, vacuum freeze drying and heat pump drying, as well as the problems existing in the research of today's honeysuckle drying processing. Honeysuckle product quality provides experience and inspiration.

Key words: honeysuckle microwave drying; heat pump; microwave; vacuum freezing; review

Honeysuckle is a traditional Chinese herbal medicine widely distributed in various provinces of China. It is harvested and dried before the opening of summer flowers. According to modern medical analysis, honeysuckle is rich in various types of chemical components such as chlorogenic acid, luteolin and triterpenoid saponin, and its preparation has obvious inhibitory effect on bacteria such as pneumococci.

With its medicinal value widely recognized, the planting scale of honeysuckle has expanded year by year, and the output has increased year by year. However, what kind of drying technology should be used for deep processing of honeysuckle after harvesting, so as to produce high quality and high efficacy honeysuckle products, has been the hotspot and difficulty of honeysuckle research in recent years. The article summarizes the advanced drying technology at home and abroad, provides experience and inspiration for improving the quality of honeysuckle products, and explores reasonable ways of drying and drying of honeysuckle.

Honeysuckle dry status

Drying is an important part of the processing of honeysuckle. Since fresh honeysuckle is prone to browning, it needs to be dried immediately after picking to avoid effective dispersion. However, most of China's honeysuckle drying processing still uses traditional methods such as drying, drying, and sulfur smoking. Not only is the efficiency low, but the quality of honeysuckle products cannot be guaranteed. This paper sorts out the development and application of various advanced drying technologies, and provides a reference for exploring reasonable ways of drying honeysuckle.

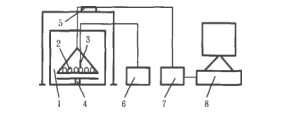

China has been researching and applying microwave drying technology since the 1970s, and has been used in food, tobacco, medicinal materials, wood and other industries. In terms of drying of traditional Chinese medicine, microwave drying technology has been widely used in traditional Chinese medicine extracts, capsules, tablets, etc. in recent years due to its advantages of high speed, high efficiency, and uniform heat.

He Chunnian et al. compared the effects of five drying methods such as microwave drying on the content of active constituents in Astragalus membranaceus. The experiment showed that the content of total flavonoids in the leaves of Astragalus membranaceus was the highest by microwave drying. Zhang Wei et al. used microwave drying of Salvia miltiorrhiza var., and determined that the texture and appearance quality of Danshen medicinal materials were better than that of dry and dried at 60 °C, but the content of tanshinone was the lowest. If microwave drying is used below 60 ° C, the tanshinone content can be effectively maintained, but the drying efficiency is significantly reduced.

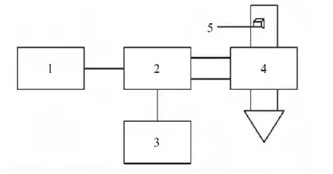

It is known through experiments that the limitation of drying by microwave alone is large. Therefore, other drying techniques need to be added to compensate for the defects of microwave drying. Li Jing et al. used a microwave-vacuum combined drying technique to dry the honeysuckle. The results showed that microwave vacuum drying kept the shape and color of honeysuckle to the utmost extent, and the chlorogenic acid content of the index component of honeysuckle was significantly higher than that of common drying methods.

China's honeysuckle market management and research level is still in its infancy. In terms of market management, it is necessary to further guide the development of the honeysuckle industry and formulate an authoritative industry standard for honeysuckle settlement to protect the interests of flower farmers. In terms of scientific research, the theory of honeysuckle drying has been preliminarily established due to the encouragement of research by national fund projects. However, there is no consensus on the selection of drying technology, and the limitations of various drying technologies are not well understood. Therefore, drying technology is needed. Combine with the craft to explore the best process.

In terms of equipment development, traditional drying equipment still occupies the market, and the research and development power for the special drying equipment for honeysuckle is insufficient. Therefore, in the future, a lot of work needs to be done on the theoretical research of drying technology, exploring the best drying process, and developing effi