Study on Microwave Production of Beef Jerky

Key words: yak meat; dried meat; process flow; microwave drying equipment; orthogonal test

Abstract: In order to make full use of good yak resources to establish a standardized production mode and create brand-name products with broad market prospects, the experiment adopts orthogonal test method, using fresh yak meat as raw material, and microwave drying sterilization technology for yak beef processing. The best control conditions for microwave drying sterilization.

The results showed that the drying time was 9 min, the drying temperature was 150 °C, the microwave power was 900 W, and the optimum process parameters were 500 g of block, 50 min of cooking time, and 10 °C of degraded temperature. Products with brighter color, better tenderness and longer shelf life.

The processing of yak meat should be developed from primary processing to high processing level and high added value, highlighting the characteristics of yak beef green and pollution-free, making full use of good yak resources, establishing standardized production mode, and creating brand-name products with broad market prospects. .

Reduce the impact on the product

The measurement of the total number of bacteria in the slowing process shows that: This is the most basic and important process for making yak meat. It is necessary to master the temperature and time to lay the foundation for the subsequent process; therefore, considering the overall processing benefits The optimum temperature is 10 °C and the slowing time is 12 h.

Selection of key control points for various processing steps, accessories and appliances

In the processing of yak meat, the micro-organisms in the dicing and dicing process are obviously increased. It is speculated that the hands, contact tools and countertops of the yak meat products are not thoroughly cleaned and disinfected, and the accessories themselves have more Microorganisms cause pollution, so the hands, accessories, contact utensils and equipment of personnel are the key control points for the processing of dried beef products.

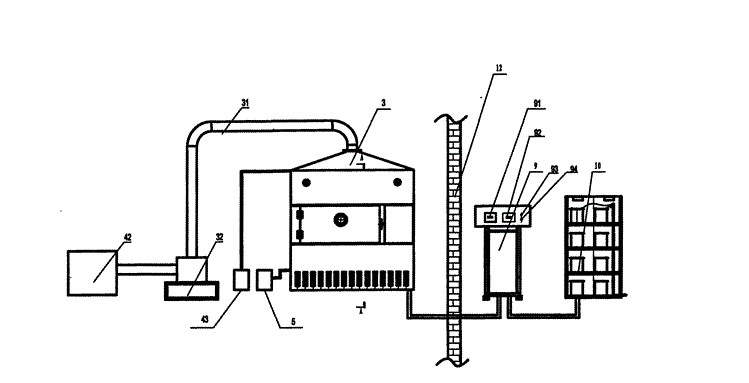

The impact of microwave technology on product quality

Through the comparison of traditional technology and microwave technology, the advantages of microwave technology are fast speed, instantaneous temperature rise, uniform heating of all parts, avoiding the temperature gradient formed by the external heating method from the external heating method, resulting in uneven heating, and the microwave drying sterilization technology Yuyu beef is processed and processed for a short period of time. The products are superior to traditional dried meat in terms of color, tissue state and storage.

The drying time has a great influence on the quality of beef jerky, because the drying time is short, the amount of dehydration is small, the concentration of flavor substances in the product is low, and the taste cannot be fully scented; the drying time is long, the product is too dry, the taste is strong, and the taste is poor; therefore, Drying time and temperature are important factors in the quality of beef jerky.

The cooking temperature and time have different effects on the quality of the product. The cooking time is too long, the nutrient loss is serious, the product is not well chewed, the taste is not good; the cooking time is too short, and the product is not well matured.

in conclusion

The best control conditions for microwave drying of yak meat: drying time 9 min,

Drying temperature 150 °C, microwave power 900 W; Optimal process conditions: cooking time 50 min, block gage 500 g, thawing temperature 10 °C.