Research progress on tilapia drying processing technology

Abstract: Drying is one of the important methods of tilapia processing. Tilapia dried foods can meet the requirements of consumers in terms of nutrition, color and flavor, and are easy to preserve and widely loved by consumers.

The main techniques used in tilapia drying are: microwave drying equipment, heat pump drying, vacuum freeze drying, vacuum microwave drying, supercritical CO2 drying, and combined drying. This paper will discuss the types, advantages and disadvantages, research progress, application status and development trends of tilapia drying processing technology in recent years.

Key words : tilapia microwave drying; processing; energy saving; research progress

China has become the largest country in the cultivation and production of tilapia. In the past 10 years, its output has increased at an average rate of about 14.75% per year. The output accounts for about one-third of the world's total, ranking first in the world. Tilapia is currently important in China. One of the freshwater aquaculture species is also one of the freshwater fish species with the most international competitiveness and industrialization prospects. Tilapia has the characteristics of fast growth, good meat quality, high yield and rapid reproduction. It has become a worldwide farmed fish with high economic value. It is also regarded as one of the main sources of animal protein in the future. It is rich in nutrients and tastes. Tasty and other advantages.

Because the water content of tilapia is about 70%, it is easy to rot and deteriorate. In order to maintain the quality of tilapia meat, it is necessary to adopt effective processing technology and reasonable storage processing. At present, the storage and processing methods of tilapia are mainly dry processing and freezing processing.

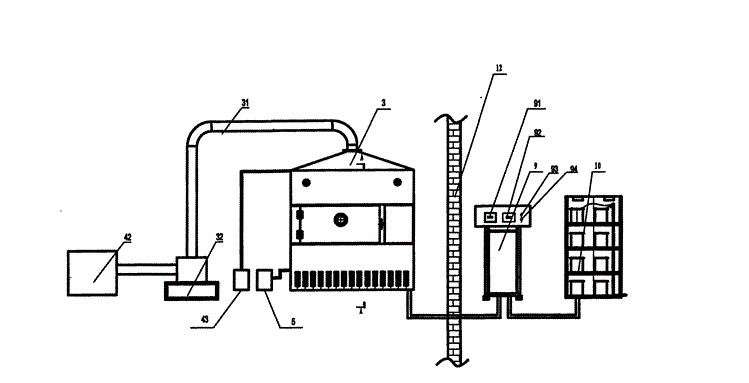

The freezing process is relatively simple, but the initial investment of the equipment is large, and the transportation cost is higher in the later stage. Dry processing is a traditional technique commonly used in the preservation of aquatic products and is one of the important processes in the processing of aquatic products. Drying is an extremely complicated process. The research on drying methods of tilapia at home and abroad mainly includes: hot air drying, heat pump drying, vacuum freeze drying, vacuum microwave drying, supercritical CO2 drying, combined drying (CD).

Each drying method has its own advantages and disadvantages, and there is no drying method to meet all technical requirements of the product. This paper mainly analyzes the characteristics of tilapia drying technology, and proposes the future development trend of tilapia drying processing technology, aiming to promote the research and development of tilapia deep processing technology in China.

Drying technology is a cross-disciplinary science that involves a lot of knowledge and a wide range of applications. Tilapia drying involves the physical and chemical properties of the materials and the properties of the products, energy transfer theory of heat transfer, mass transfer, fluid mechanics and aerodynamics, as well as the characteristics and practical properties of different drying treatment methods. The drying process should consider three basic technical indicators at the same time, that is, the drying operation should ensure the quality and quality of the product, the drying operation should be environmentally friendly, and the drying process should be as energy-saving as possible and reduce the production cost.

The research on the drying technology of tilapia also mainly focuses on these aspects. The basic theoretical research mainly focuses on the improvement of product quality and the improvement of technology. The research of practical application is mainly based on the basic theoretical research, paying more attention to energy conservation and environmental protection and reducing costs. Therefore, in order to meet the actual needs of production, the research of combined drying method is a hot spot of current research.

By complementing the advantages of several drying methods, combined drying of materials in stages or simultaneously has become a trend. However, the joint drying process, process parameters, determination of drying transition points, mechanism research, and reasonable model establishment also require a lot of experimental work, which is a development direction of tilapia drying. Therefore, carrying out in-depth research on drying processes and equipment is of great significance for improving the processing level of tilapia and promoting the development of China's fishery economy.