Study on Microwave Drying Kinetics of Longan

Absrtact: Aiming at the problem of non-uniform heating of longan raw materials and excessive microwave drying rate and local overheating, the method of combining intermittent microwave with variable power microwave was adopted to dry longan. The changes of moisture ratio and drying rate of longan pulp during vacuum microwave drying were analyzed from three aspects: microwave drying equipment, vacuum degree and loading capacity, and a thin layer fitting model was established. The orthogonal test of power density, vacuum degree and loading capacity was established to optimize the intermittent vacuum microwave drying process of longan by taking color, total phenol content and rehydration as the evaluation indexes.

Key words: longan microwave drying; intermittent vacuum microwave drying; kinetics; nutritional quality

Longan is a famous tropical and subtropical fruit in China. As the origin country of longan, China accounts for 73.6% of the world's planting area and 59.7% of the world's output. Longan pulp is rich in sugar, polyphenols and other nutrients and active substances. As early as in the Compendium of Materia Medica, Longan has been recorded as a good source of resources. Modern medicine has also proved that Longan has anti-aging, immune enhancement and other effects, and is a good product for tonifying qi and blood.

However, longan ripens in summer, harvesting time is short and flesh moisture is high, after harvesting, metabolism is vigorous, respiratory function is strong, easy to rot and deteriorate, so dried longan is the main processing products of longan. The traditional drying methods of longan mainly include sun-drying and fire-baking. These two methods have some defects, such as serious nutritional loss of the original fruit, deeper pulp color, uneven drying process, which affect the market sales of longan. Zhang Xiangyang et al. found that vacuum microwave drying can effectively reduce the chemical and enzymatic reactions of longan pulp color and flavor substances, and better retain the original flavor of longan.

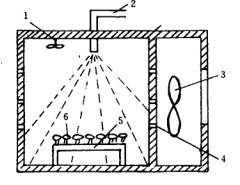

Vacuum microwave drying is a new drying technology developed in microwave and vacuum technology. It has the characteristics of high efficiency, low energy consumption and oxygen isolation. However, microwave heating efficiency and drying rate are too fast, which easily lead to the phenomenon of "hot spots" leading to local overheating. Intermittent microwave drying is a discontinuous microwave drying process with a "slow sulphur" stage. Intermittent stage can distribute moisture and temperature equally, increase drying rate in the next stage, and control temperature effectively. It is suitable for thermal sensitive materials. In the present study of vacuum microwave drying, microwave usually uses constant power, but the moisture content changes constantly in the drying process, especially in the later stage of drying. Excessive microwave energy density will lead to excessive drying of materials, which will destroy the thermosensitive nutrients and reduce the quality.

In this study, the vacuum microwave drying of longan was carried out by combining intermittent microwave with variable power microwave. The changes of water ratio and drying rate of longan pulp during vacuum microwave drying were analyzed from three aspects of power density, vacuum degree and loading capacity. A thin layer fitting model was established and the technological conditions of intermittent vacuum microwave drying of longan were optimized in order to develop high efficiency. New dry processing technology of longan with energy saving and quality assurance provides theoretical support.