Effect of Microwave Drying on Soybean

ABSTRACT:

In view of the influence of power change in microwave drying equipment,

the soybean with 20% initial wet base moisture content was used as the model material.

When the power density was 0.8 W/g, 0.6 W/g and 0.4 W/g, the microwave drying was carried out with four schemes, and the drying was stopped when the burst waist rate exceeded 5%.

The results showed that in the drying process, the higher the power density, the lower the wet base moisture content of soybean, and the more energy needed. In the process of microwave drying soybeans with different power densities, the power density should not be too high at the beginning of drying. There is no need to increase power density in the later stage of drying process, and excessive power density will cause a lot of waste of energy. Reducing different power density in microwave drying stage can effectively improve energy utilization efficiency.

Key words: microwave drying soybean; power density; multi-stage; energy

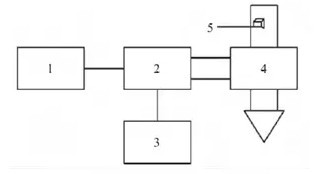

Microwave technology is more and more widely used in the field of medicine. Tan Wei and others have studied the design and application of microwave hot air combined drying equipment in the drying of medicinal materials. In microwave drying, temperature and drying rate can be adjusted and controlled by changing the power density. In order to obtain high quality products, microwave power control is particularly important. Many domestic scholars have studied the effects of microwave on biomass, apple pomace, carrot and dried carrot under different power.

Domestic and foreign scholars believe that power is a very important research factor in microwave drying process. In this paper, the drying kinetics, waist bursting rate, drying efficiency and energy consumption of soybean were studied by choosing different microwave power and using multi-stage microwave drying with different power densities.

The multi-stage and different power densities refer to different power densities in the microwave drying process. Each power density corresponds to a drying stage, and the effects of different power densities in different stages on soybean quality are studied.

In this paper, we choose soybeans sold in the market. During the experiment, we choose dry soybeans with full grains and smooth surface. According to the initial wet base water content measured before the experiment, we soak them in water at room temperature (24 C) for different time, then put them in a sealed polyethylene bag and keep them in constant temperature for 72 hours. We take them out 2 hours before the experiment and reunite them to the same wet base water content.