Microwave Penetration Depth of Poplar with Different Moisture Contents

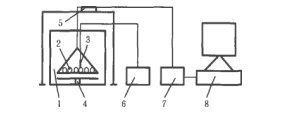

Absrtact: The microwave penetration depth of poplar wood with different moisture content was theoretically studied by using microwave drying equipment,

and the effects of microwave frequency and moisture content of poplar wood on Microwave penetration depth were explored.

The results showed that the penetration depth of 2.45 GHz microwave decreased from 22.30 cm to 3.64 cm when the water content of poplar increased from 30% to 110%, and that of 0.915 GHz microwave decreased from 60.32 cm to 9.85 cm, and the temperature uniformity of poplar decreased with the increase of water content.

The results show that the thickness of the sample should be controlled within the microwave penetration depth during wood drying, which can effectively improve the drying uniformity.

Key words: finite element method, microwave heating, microwave penetration depth, microwave drying of poplar, Drying Uniformity

Microwave technology originated in the 1930s and is mainly used in the field of communication. With the progress of science and technology and the expansion of social demand, microwave technology has developed rapidly, and has been extended to the drying of biomass materials, food processing, sewage treatment and other fields.

In the 1960s and 1970s, this technology began to be applied in wood drying. Its basic principle is as follows: when the water molecules in wood are subjected to microwave action, electrons will migrate, which makes the water molecules in wood produce vibration and friction heat. In this process, electromagnetic energy is rapidly converted into heat energy, which provides a new way for rapid and efficient wood drying.

Compared with traditional hot air drying, microwave drying uses high frequency microwave to penetrate the wood instantaneously, forming high temperature inside the wood, vaporizing water, generating vapor pressure, opening the water transfer path inside the wood, realizing the rapid transmission and evaporation of water, and shortening the drying time of wood.

However, the industrial application of microwave drying is limited by some unfavorable factors, such as uneven heating of wood and limited penetration depth of microwave. In the process of microwave drying of wood, the excessive size of wood causes the local temperature to rise too fast, which is easy to cause drying defects, such as cracking and carbonization. A lot of research has been done on the uniformity of temperature distribution in microwave wood drying. In order to further solve the uniformity of wood microwave drying, the depth of wood microwave penetration has been explored in this paper.

In the process of microwave transmission in wood, energy decreases because it is absorbed by water molecule, so the ultimate penetration depth of microwave is limited. Mou Qunying et al. studied Citi pine through theoretical deduction. It was found that when the moisture content of Citi pine is higher than 40% at microwave frequency of 2.45 GHz or 0.915 GHz, the penetration depth of microwave is within 6 cm to 16 cm, and there is no more correlation at present. Theoretical research reports, therefore, it is of great significance to further explore the penetration depth of microwave wood drying in theory.

In this paper, the microwave penetration depth of poplar wood was studied by finite element method, and the effect of moisture content and microwave frequency on the microwave penetration depth of poplar wood was explored, which provided theoretical basis for the improvement of microwave drying equipment and experimental research.