Effect of vacuum microwave drying on main carotenoids in pumpkin slices

Abstract: The main carotenoids in pumpkin slices were qualitatively and quantitatively determined by C30 column and high performance liquid chromatography-diode array detection-atmospheric pressure chemical ionization tandem mass spectrometry. The effects of vacuum microwave drying conditions on the composition and content of carotenoids in pumpkin slices were studied.

Microwave drying equipment had the greatest influence on carotenoids in pumpkin slices, followed by vacuum and slice thickness. With the increase of microwave intensity, the total carotenoid content in pumpkin slices decreased significantly (P < 0.05), and the total carotenoid content in dried pumpkin slices increased to a certain extent with the increase of vacuum and slice thickness.

Key words: pumpkin slices microwave drying; vacuum microwave drying; carotenoids

Pumpkin is widely planted in China. Besides amino acids, vitamins, carbohydrates, pectin and trace elements, it also contains rich carotenoids, especially alpha-carotene and beta-carotene, which have the functions of anti-oxidation, anti-cancer, prevention and treatment of cardiovascular diseases and immune system disorders. Pumpkins in China are mainly used for fresh food with small processing capacity, and often rot because they can not be sold or processed in time.

Drying is the most common preservation method of fruits and vegetables. Deep processing of harvested fruits and vegetables by drying can prolong their preservation time and increase the added value of products. However, the loss of carotenoids in pumpkin drying process is a common phenomenon, resulting in deterioration of color and nutritional value, greatly affecting the quality of dried products.

Zou Yuxiao and others studied the effects of hot air drying and heat pump drying on the dry quality of pumpkin. The results showed that the dry color of pumpkin became darker after drying, and the loss rate of carotenoids was more than 50%. Nawirska et al. also reported that the total carotenoid content of pumpkin decreased significantly after microwave drying, vacuum drying and hot air drying.

Vacuum microwave drying is the combination of microwave and vacuum drying, which has obvious advantages in improving the quality of fruit and vegetable products. On the one hand, microwave provides a uniform heat source for vacuum drying, on the other hand, the vacuum environment enables materials to complete drying at a lower temperature, which can better retain the original color, fragrance and bioactive functional components of products. Compared with other drying methods, microwave drying has the advantages of fast, low temperature, high efficiency and safety.

Ding Yuanyuan et al. showed that the content of beta-carotene in sweet potato chips dried by vacuum microwave was much higher than that dried by hot air. Cui Zhengwei et al. found that the retention rates of carotenoids and chlorophyll were 95.7% and 97% after vacuum microwave drying of carrot slices and leek. Durance et al. compared the effects of vacuum microwave drying and hot air drying on the quality of carrots. The results showed that the color, VC and alpha-carotene content of carrots after vacuum microwave drying were significantly better than hot air drying.

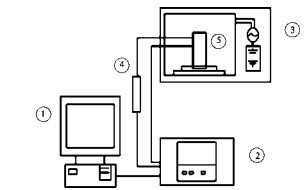

However, there are few studies on the composition and content of carotenoids in pumpkin under different vacuum microwave drying conditions. Based on this, the effects of three drying parameters (microwave intensity, vacuum degree and material slice thickness) on the composition and content of carotenoids in pumpkin slices under vacuum microwave drying conditions were studied in order to be the most important in the vacuum microwave drying process of pumpkin. It provides theoretical basis to retain carotenoids to a large extent.