Effect of microwave drying conditions on the drying characteristics of raspberry puree

Abstract: in order to study the microwave drying of raspberry fruit pulp heat transfer characteristics with framberry as raw materials, using the central composite experimental design method, the influence of drying conditions on material temperature, moisture content and dielectric properties, heat and mass transfer process of the microwave drying process of foam.

Raspberry puree during the microwave drying process, the drying period, the dielectric constant and dielectric loss factor were increased, which can increase the microwave absorption of materials, pulp temperature from room temperature up to 70 DEG C, water content had no obvious change;

The drying medium, the dielectric constant and dielectric loss factor increased first and then decreased, so the microwave energy absorbed by material was first increased and then decreased, pulp water content decreased from 90% to 40%, the temperature change is not obvious; the next stage of drying, the dielectric constant and dielectric loss factor decreased, microwave absorbing materials can reduce fruit pulp, moisture slowly dropped to about 15%, the temperature continues to rise. Microwave drying equipment can effectively improve the drying rate of high viscosity pulp.

Keywords: microwave drying of raspberry, dielectric properties, heat transfer, mass transfer

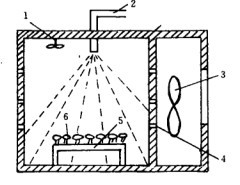

Raspberry fruit water content is about 90%, easy to damage the soft texture, easy transportation and storage. The drying process is to extend the storage period of the feasible method of raspberry. Microwave drying fast heating rate, the heat transfer ability; drying technology for high sugar content and high viscosity materials. Combined with the advanced microwave drying and foam drying two methods, microwave drying method in the dry foam quality is better than hot air drying, freeze drying drying is better than in terms of efficiency, and convenience is better than spray drying drying equipment.

The use of microwave drying method of foam dry berry pulp has advantages: fast heat transfer; water evaporation area; high drying rate; low temperature drying. The processing of the berries by microwave drying method, drying the product quality can meet the current market demand.

Drying technology has been widely used in fruits and vegetables and processing of agricultural products, such as mango, papaya, cantaloupe muskmelon, etc.. At present, domestic and foreign scholars have done research on microwave drying and heat transfer process. In order to simplify the calculation, the physical parameters as a constant, but need to add correction factors to reduce the deviation with the actual situation, and considering the material dielectric properties with temperature, moisture content, accurate analysis of material of microwave energy absorption and transformation process.

The heat and mass transfer mechanism of microwave drying process, help to absorb, transfer and distribution of water and temperature variation in the internal high viscosity material to essentially illuminate microwave, microwave high viscosity material processing quality control. This paper intends to reveal the mechanism of heat and mass transfer in the drying process. The research contents are as follows: the influence of microwave drying conditions on the material temperature, moisture content and dielectric properties; a dielectric characteristics of water and temperature, the rate of regression model, analysis of heat and mass transfer in the process of microwave drying process.