Study on Microwave Drying of Peony Seeds

ABSTRACT: In order to explore a method of drying peony seeds quickly and with better quality after drying, in order to prolong the storage time and ensure the quality of pressed oil, microwave drying experiments were carried out on Peony seeds.

The microwave drying characteristics of peony seeds were studied by choosing heating time, intermittent time and material layer thickness of microwave drying equipment as experimental factors. The drying rate, shell bursting rate and ripening rate of peony seeds were taken as evaluation indexes. Orthogonal experiments were carried out on Peony seeds. The optimum technological parameters of microwave drying of peony seeds were obtained by comprehensive balance method.

The results showed that the water loss process of peony seeds was mainly at the constant speed stage. Different microwave drying parameters had different effects on the microwave drying characteristics of peony. When the drying time was 20 seconds and the drying time was 60 seconds, and the material layer thickness was 2 layers, a faster drying rate could be obtained under the premise of guaranteeing the quality of peony.

Key words: microwave drying of peony seeds; intermittent time; orthogonal test

Peony is the national flower of our country. Peony seed is the essence of peony crystallization. It is the fruit protected by the double layer of fruit shell and seed shell. Peony seed oil can reduce blood pressure and blood lipid, and has high medicinal and economic value. Peony seeds must be dried before storage to prevent their mildew and deterioration from affecting subsequent deep processing.

The traditional drying method of peony seeds is air-drying, which has a long drying cycle, is easy to mildew and needs a lot of air-drying space, which greatly limits the development of peony industry. Therefore, it is urgent to find a better drying method of peony seeds.

At present, the main drying methods are hot air drying, far-infrared drying, vacuum freeze-drying and microwave drying. Among them, hot air drying has some problems, such as long drying time, low drying efficiency and energy utilization rate; far infrared drying and vacuum freeze drying have better drying quality, but high investment cost; microwave drying has fast drying rate and high thermal effect, which can control moisture content in a safe storage range in a relatively short time, good quality after drying, and can sterilize.

The research on microwave drying of agricultural and sideline products started in foreign countries more than 20 years ago. In recent years, more and more domestic reports on microwave drying of coriander, ginkgo, longan and other aspects have been reported. Some of them have been successfully applied and have achieved remarkable economic benefits.

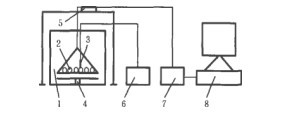

However, the unreasonable setting of microwave drying parameters can easily make peony seeds burst and ripen. The purpose of this experiment is to find out a kind of microwave drying technology parameter which can not only dry the peony seeds quickly but also has low shelling rate and ripening rate, so as to provide a basis for the research and design of industrial drying equipment. Therefore, the intermittent microwave drying of peony seeds was studied in this paper.