Microwave Drying Characteristic and Kinetic Model of Carrot

ABSTRACT: In order to study the microwave drying characteristics of carrots, the drying experiments with different microwave power (406, 567, 700 W), slice thickness (2, 4, 6 mm) and material loading (30, 40, 90 g) were carried out. The drying characteristic curve of water loss rate, dry base moisture content and the effect of effective moisture diffusivity Deff were discussed, and the thin-layer drying kinetics model of carrots was constructed.

The results showed that the microwave drying equipment of carrot was divided into pre-heating drying stage, constant-speed drying stage and slow-speed drying stage, and the time of constant-speed drying process was shorter. When microwave power was 700 W, slice thickness was 6 mm and loading was 30 g, the drying effect was the best. Through regression fitting analysis, Page kinetic model was the most suitable model to describe the microwave drying process of carrot, and the model determination coefficient R2 was the best. The maximum error of validation test is 6.91.

Key words: carrot microwave drying; drying characteristics; dynamic model; Page model

Carrot is a crisp, delicious and nutritious home vegetable, known as "Little Ginseng". Because of its high nutritional value and health care effect, it is very popular with consumers. The common methods of carrot drying are infrared drying, hot air drying and natural air drying. Infrared drying and natural air drying are less used because of long drying time and low efficiency. Hot air drying is the most widely used method in carrot drying. However, there are many problems in hot air drying, such as high energy consumption, uneven drying and large equipment volume.

As an advanced drying technology, microwave drying has the advantages of fast drying rate, uniform drying, energy saving and environmental protection. It is the development trend of agricultural by-products drying, and has been widely used in rice, white fruit, bitter gourd and other agricultural products. However, there are few reports on microwave drying characteristics and application of carrots.

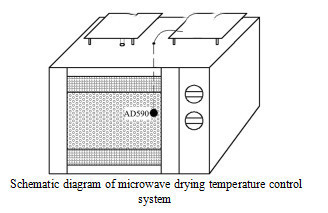

In order to investigate the microwave drying characteristics of carrots, the drying experiments with different microwave power, slice thickness and material loading were carried out in order to obtain the drying characteristic curves of water loss rate and dry base moisture content, clarify the mechanism of different parameters affecting the effective water diffusion coefficient, construct a thin-layer drying dynamic model of carrots, analyze its heat transfer characteristics and water diffusion law, in order to improve the drying performance. The theoretical basis for improving the drying efficiency and quality of carrot was provided.

Choose carrots with good appearance, uniform thickness and no decay, wash and drain them into slices of equal thickness. Place carrots with a certain load on a self-made heat-resistant material mesh tray, take them out every 1 minute, measure their quality, take out time is controlled within 20 seconds, and dry them until constant weight.

The effects of microwave power on microwave drying characteristics of carrot slices were 406 W (medium-low fire), 567 W (medium-high fire) and 700 W (high fire), respectively, when the thickness of carrot slices was 4 mm and the microwave power was 567 W. The effects of microwave power on microwave drying characteristics of carrot slices were 30 g, 60 g and 90 g, respectively, when the thickness of carrot slices was 4 mm and the microwave power was 567 W. The effects of slice thickness of 2 mm, 4 mm and 6 mm on microwave drying characteristics of carrot were studied when the loading was 60 G.