Effect of Microwave Intermittent Treatment on Drying Characteristics and Quality of Broiler Wing Roots

The effects of microwave power density (_= 3.31, 4.43, 5.59 W/g) and intermittent ratio (PR= 1, 2, 3) on the drying characteristics and quality of broiler wing roots were studied. The results showed that the microwave drying equipment of broiler wing roots was mainly a constant drying process, and the changes of moisture content and drying rate were significantly affected by microwave treatment conditions (P<0.05).

By comparing and analyzing the regression statistical results of eight drying empirical models, it was determined that Page equation was the best drying model (average R2 = 0.9958, average 2 = 0.0003), which could accurately predict the moisture content of broiler wing roots during microwave intermittent drying (PR = 1, 2, 3).

The specific energy consumption of different microwave treatment conditions was 13.48-17.97 MJ/kg, and the effect of batch ratio was significantly higher than that of power density (P<0.05). Microwave batch treatment can reduce the longitudinal shrinkage rate (LSR) and improve the appearance integrity of the samples. At the same power density, the shear stress values obtained by batch treatment are lower than those obtained by continuous treatment.

Key words: wing root microwave drying, microwave intermittent treatment, drying characteristics, drying model, quality

Microwave refers to electromagnetic waves with frequencies ranging from 300 MHz to 3000 GHz. When the material is placed in the microwave electric field, the dipole which originally carried out irregular thermal motion rubs and generates heat along with the fast orientation rotation of the high frequency alternating electromagnetic field repeatedly, which makes the moisture in the material rapidly absorb heat and evaporate. The microwave penetrating force is strong, which can make both inside and outside of the material heated, temperature gradient and water ladder. High drying rate can be achieved with the same degree orientation.

At present, there are many studies on microwave drying in aquatic products: Darvishi and so on. The microwave drying characteristics of sardines are studied. It is found that the drying rate increases with the increase of microwave power. When the power is 200~500 W, the D of the samples is 7.158 * 10-8 ~ 3.408 * 10 7m2 / S. Through fitting the data, it is found that the Midilli equation is the best drying mold for microwave drying of sardines. Type.

Oyster was dried by microwave with medium intensity (microwave density 5, 8) and the results showed that the microwave drying process followed Page equation. Wu et al. compared the effects of hot air drying and microwave drying on nutrition and flavor of grass carp. Compared with hot air drying, microwave drying had lower fat loss rate, lower anisidine value, higher protein solubility and no significant difference in flavor.

Compared with continuous drying, microwave intermittent drying can effectively avoid the problems of bursting or burning of drying materials. It is one of the drying methods to improve energy efficiency and drying product quality. There are few studies on intermittent microwave drying in meat products.

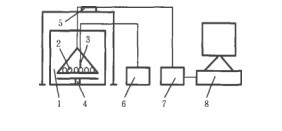

The effects of microwave power density and batch ratio on drying kinetics of broiler wing roots were studied, and the quality of finished products was analyzed in order to provide reference for broiler wing processing and production.