Study on Kinetics Model of Carya cathayensis Microwave Drying

Absrtact: In view of the problems of low drying efficiency, high energy consumption and poor quality of hickory nuts by hot air, the effects of microwave power and loading capacity on the microwave drying characteristics of hickory nuts were studied by single factor experiment. According to the law of water content change of walnut nut in microwave drying equipment, the law of water content and water loss rate of walnut nut dry base changing with time under different microwave power and loading was discussed, and the microwave drying dynamics model of walnut was established.

The results showed that microwave power had a greater effect on the drying rate of pecan nuts than the loading rate, and the microwave drying process of pecan nuts could be divided into two stages: accelerated drying stage and slow drying stage. According to the analysis, the dynamic model of microwave drying of pecan nuts satisfies Page equation. According to the drying experimental data, the drying model is solved by regression fitting with MATLAB software. The coefficient of the model is over 0.99.

Key words: Carya cathayensis microwave drying, drying characteristics, kinetic model

Carya nuts are characteristic nuts in China. Their kernels are rich in not only protein and unsaturated fatty acids such as oleic acid and linoleic acid, but also many essential amino acids and mineral elements for human body. They have high nutritional value and economic value.

However, drying has always been a weak link in the production of hickory nut products, which mainly depends on manual operation, low efficiency and high cost. Especially, the temperature and moisture content in the drying process can not be regulated reasonably, which easily leads to the insufficient coking or drying of the kernels, and seriously restricts the development of the quality and industry of hickory nut dried fruit. Carya nut is oval or oval in shape. Its shell is thick and hard. There are many compartments in the nut. The wood diaphragm is well developed. The kernels are located in the compartment.

Because of the complex structure of hickory nuts, the complex heat and water transfer coupling and cross-coupling between nuts and shells in the drying process, and accompanied by fluid phase transition, it is difficult to measure the internal temperature and water content changes. The mechanism of temperature transfer and water transfer in the drying process is still unclear.

At present, the traditional hot air drying is widely used in the production of Pecan nuts. The drying efficiency is low, the drying process is difficult to control, and the quality after drying is poor. Therefore, it is urgent to explore non-traditional drying methods to improve the drying efficiency and quality of hickory nuts.

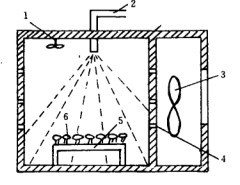

Microwave field plays an important role in promoting abnormal evaporation, rapid movement of material moisture and reducing energy consumption of drying, and it is easy to control. Microwave drying has been studied for a long time at home and abroad, but there are few studies on nuts.

Therefore, microwave technology was used to study the heat and mass transfer characteristics of hickory nuts, to explore the law of water movement in nuts, and to establish a dynamic model of microwave drying of hickory nuts, which laid a foundation for automating the drying process of hickory nuts, improving the quality of dried fruits, improving drying efficiency and reducing drying energy consumption.