Effects of three treatments on vitamin C content in different parts of jujube

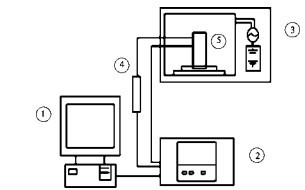

Objective To observe the effect of different treatments on the content of vitamin C in different parts of jujube. Methods The red matter was dried by electrothermal constant temperature drying method, microwave drying equipment, electrothermal constant temperature drying method and microwave drying method. The vitamin C levels of different parts of red matter were determined by iron () - phenanthroline - BPR spectrophotometry. Results The vitamin C level in pericarp was significantly higher than that in pulp (P < 0.065).

Vitamin C level in peel decreased significantly after electrothermal constant temperature drying (P < 0.05) or microwave drying (P < 0.05). Wave drying caused more damage to vitamin C, while electrothermal constant temperature drying combined with microwave drying did less damage. Conclusion Microwave electrothermal constant temperature drying combined with microwave drying can dry things more efficiently and has less damage to vitamin C. It is worth popularizing.

Key words: jujube microwave drying; vitamin C; electrothermal constant temperature drying

Red jujube is a mature fruit of the jujube genus Rhamnaceae, which was first recorded in Shennong Herbal Classic. It has the functions of invigorating qi, nourishing blood and tranquilizing mind. Jujube is rich in protein, sugar, organic acid, vitamin A, B1B, C, P and so on. Because of the suitable climate conditions, the red jujube fruits produced in Hami, Hetian and Aksu regions of Xinjiang are well colored, nutritious and of good quality.

At present, the drying amount of jujube accounts for more than 80% of all products, and most of them are processed products such as dried jujube, mud of jujube, jujube, drunk jujube, honey jujube, jujube wine, tea and beverage. However, in the processing of jujube, the loss of active ingredients, especially vitamin C, affects the nutritional value of jujube. Therefore, by comparing the effects of different treatments on the content of vitamin C in different parts of jujube, this study provides a theoretical reference for the rational processing of jujube.

In a word, stricter examination, more careful access and stronger supervision are essential. Especially, it is necessary to clarify the special requirements of the quality management system of customized medical device enterprises, such as different requirements of process, personnel, validation and standardized medical device products.

At the same time, manufacturers also need to develop appropriate risk analysis and control documents according to their own medical device products. On the one hand, to ensure the safety and effectiveness of their products, on the other hand, they also need to provide sufficient certification to the regulatory authorities to meet the requirements of registration, access and daily supervision.

In a word, the customized medical device industry needs the cooperation of manufacturers and regulatory departments to formulate appropriate, strict and feasible special requirements to ensure the safety of customized medical device users and promote the healthy development of customized medical device industry.